Inspiration for high-volume production / 2020

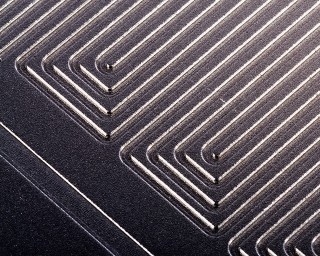

Laser Colloquium Hydrogen LKH2: fast and reliable fuel cell manufacturing

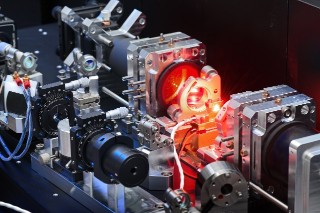

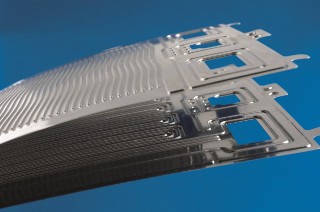

Interest in the use of fuel cells is steadily increasing as a result of the shift toward e-mobility and the broader adoption of renewable energy sources. To examine this development, the Fraunhofer Institute for Laser Technology ILT is organizing the first Laser Colloquium Hydrogen LKH2, which will take place in Aachen on March 18, 2020. The event will focus not only on laser cutting and welding of fuel cell components, but also on the execution and monitoring of the entire process chain.

more info