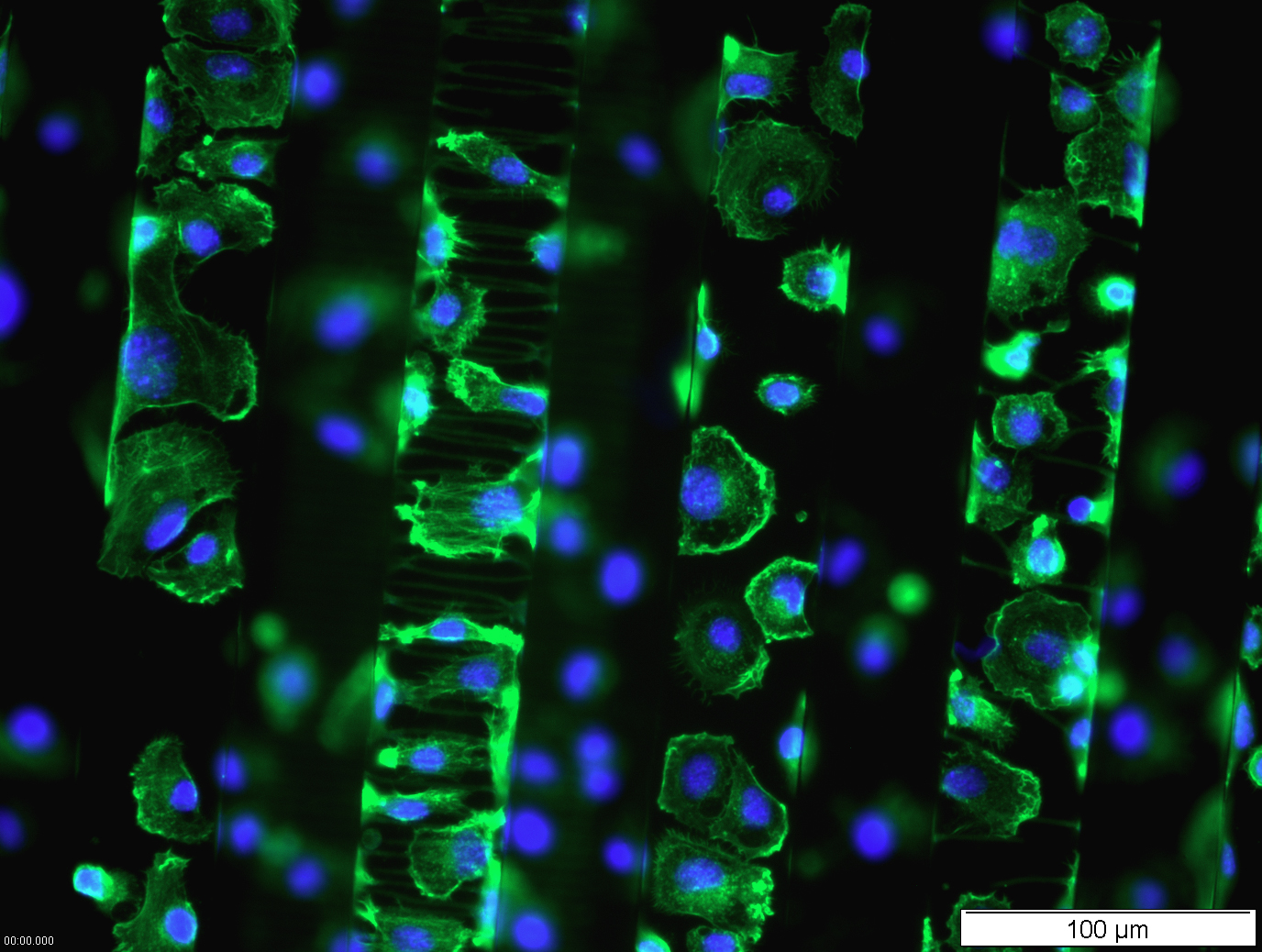

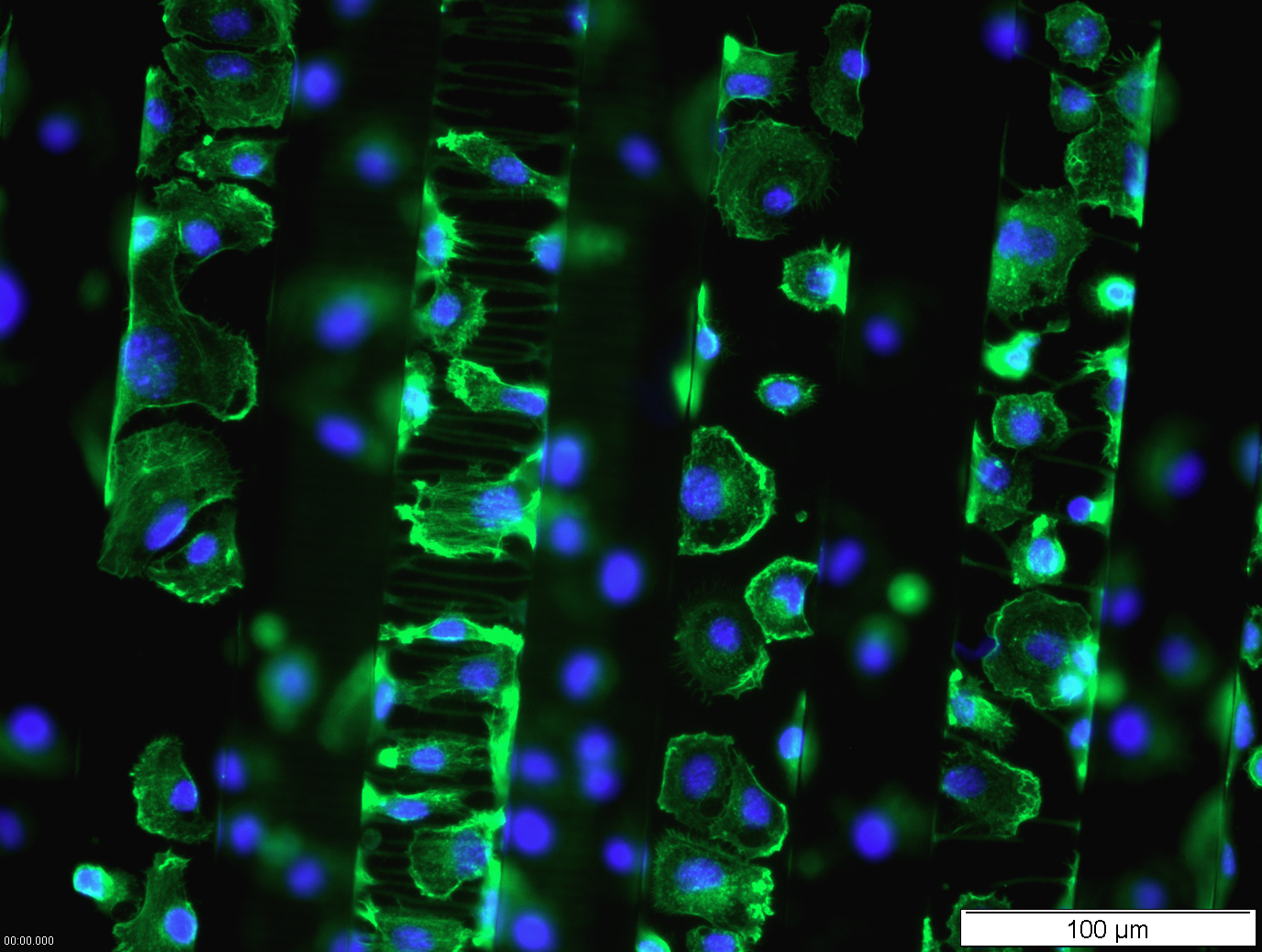

As a quickly growing interdisciplinary field, biofabrication encompasses the exploration of new conceptual ideas and tools for biomedical applications – such as specific diagnostic systems, pharmaceutical and cosmetic tissue and organs test models, as well as long-term artificial organs. These processes include the 3D printing of biocompatible materials to produce support structures for artificial blood vessels and organs, as well as the direct printing of living cells. Fraunhofer ILT is pursuing new approaches in order to rapidly print biocompatible polymers, to develop new resin formulations without toxic components and processing techniques for the flexible printing of functional cell constructs. By means of a photonic surface functionalization, these structures can be locally modified in such a way that, for example, biomolecules preferentially attach to them. In this way, biocompatible test systems can be created for research applications, pharmaceutics and the cosmetics industry.

Contact Press / Media

Dr. Jessy Schönfelder

Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP

Winterbergstr. 28

01277 Dresden

Phone +49 351 2586-360