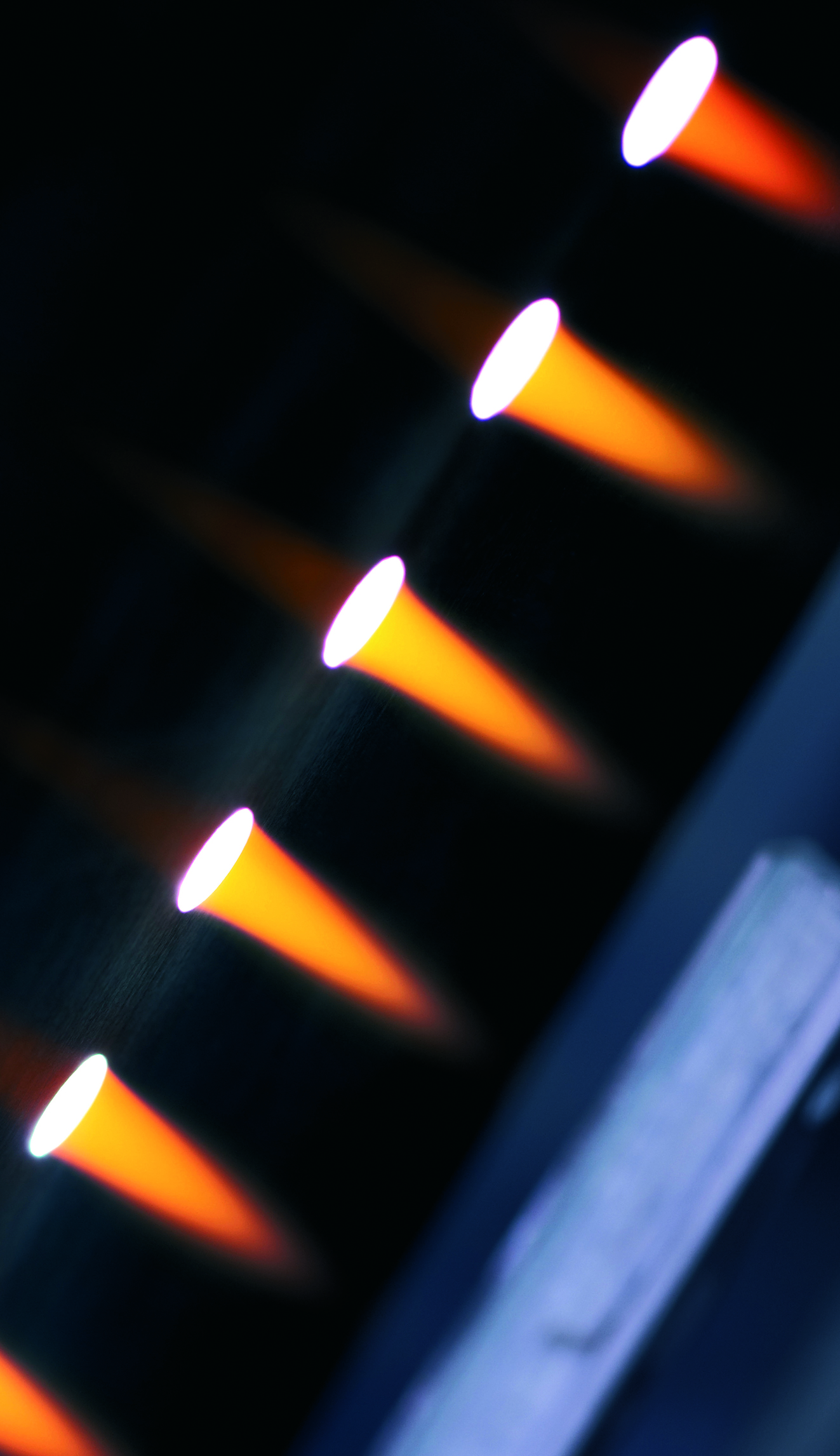

To be economical, vacuum coating processes requires high coating rates on large surfaces. The path to ever higher coating rates, particularly in the case of high-rate evaporation, is made more difficult in that the layers with a high rate of growth have a pronounced column-like structure. Also, when bonds form in reactive vapor deposition, the energy of the vapor particles is often not sufficient for a stoichiometric deposition of oxide, nitride or carbide layers. A suitable way to increase the particle energy is to use a plasma activation during evaporation. For dense plasmas, this requires powerful sources that are adapted to both a high coating rate and a large-area coating. Fraunhofer FEP has developed processes based on the combination of high-rate evaporation with different guided arc discharges (SAD and HAD process) for this purpose. The institute offers the following development services:

- Development of the coating process and the coating system

- Development and delivery of key modules (evaporators, plasma sources)

- In-situ quality control and process automation

- Plant engineering and operator know-how for plasma-activated evaporation plants

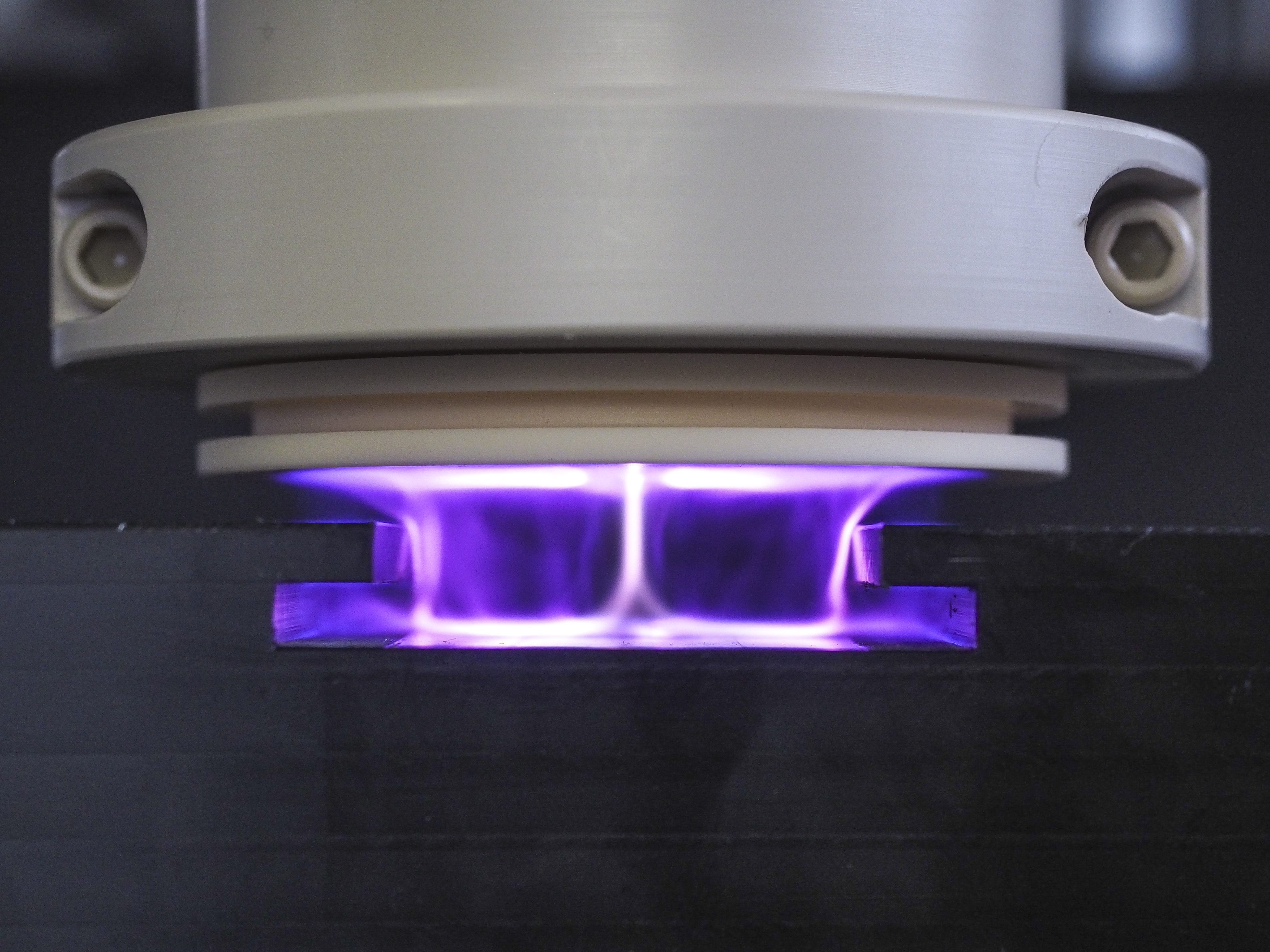

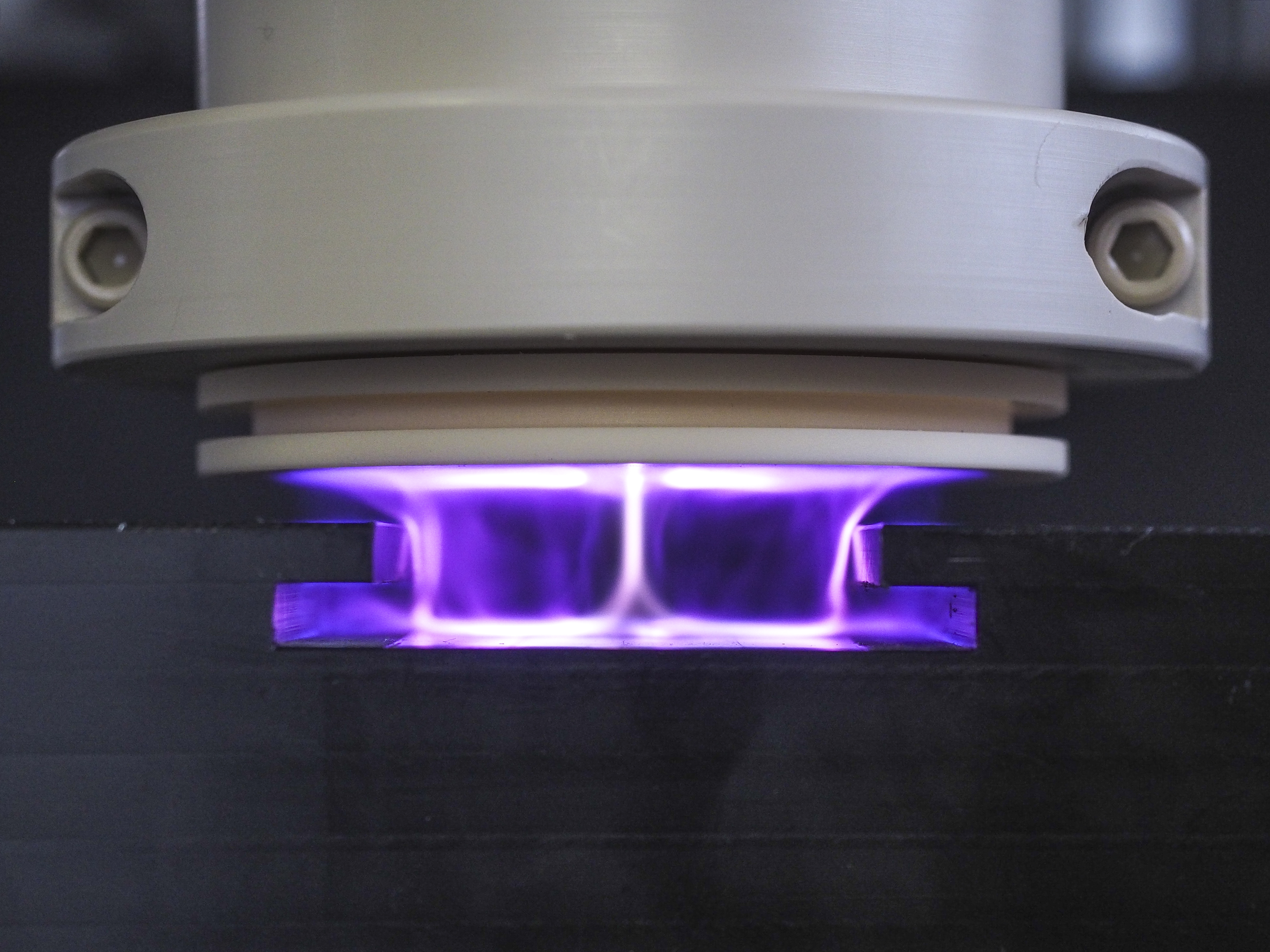

The LARGE plasma source developed at Fraunhofer IWS is characterized by the potential use of a large number of process gases, which determine the type of plasma surface modification. With its compact design, the plasma source can be easily implemented in inline processes or robot-controlled processes.