Fraunhofer Group for Light & Surfaces

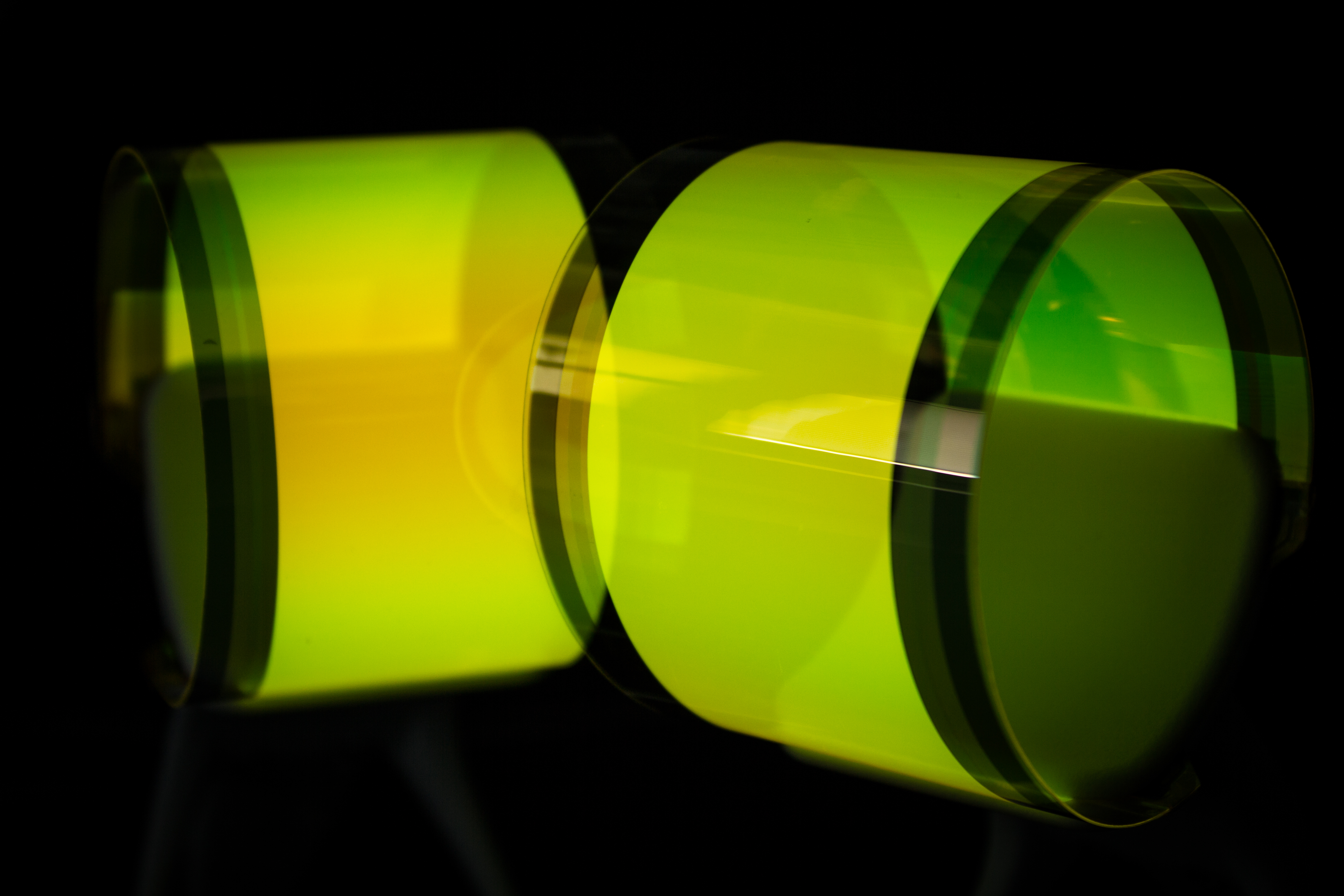

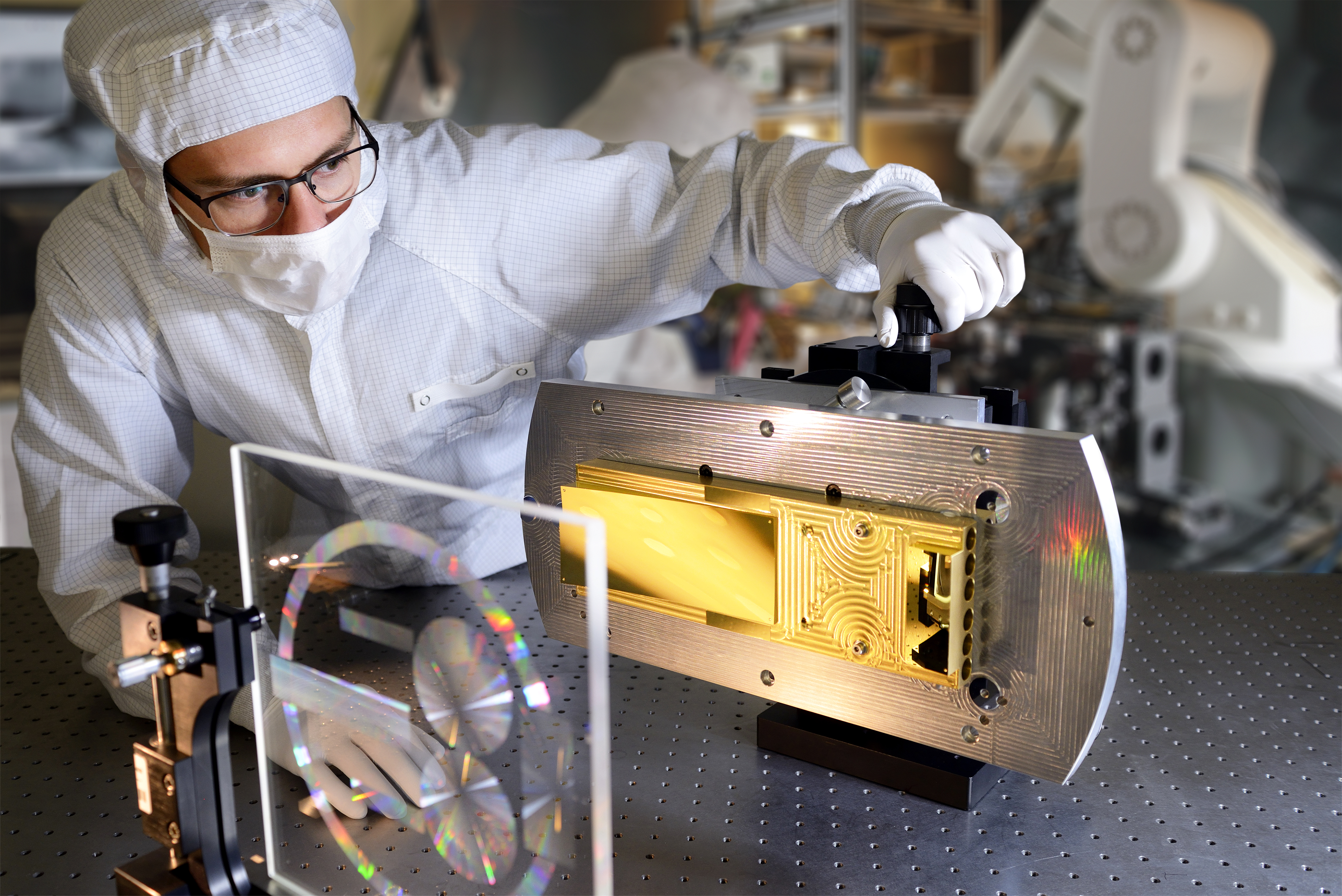

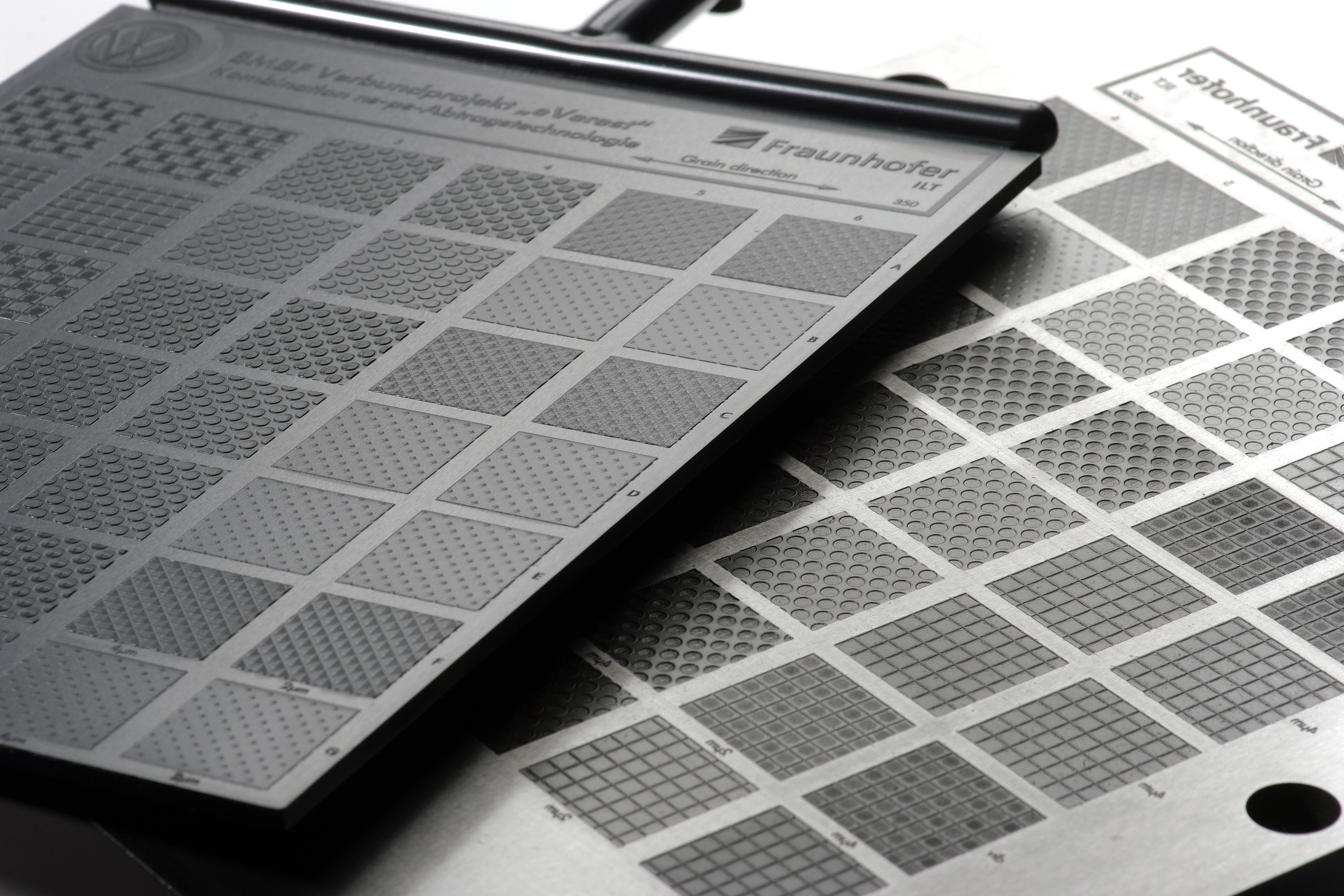

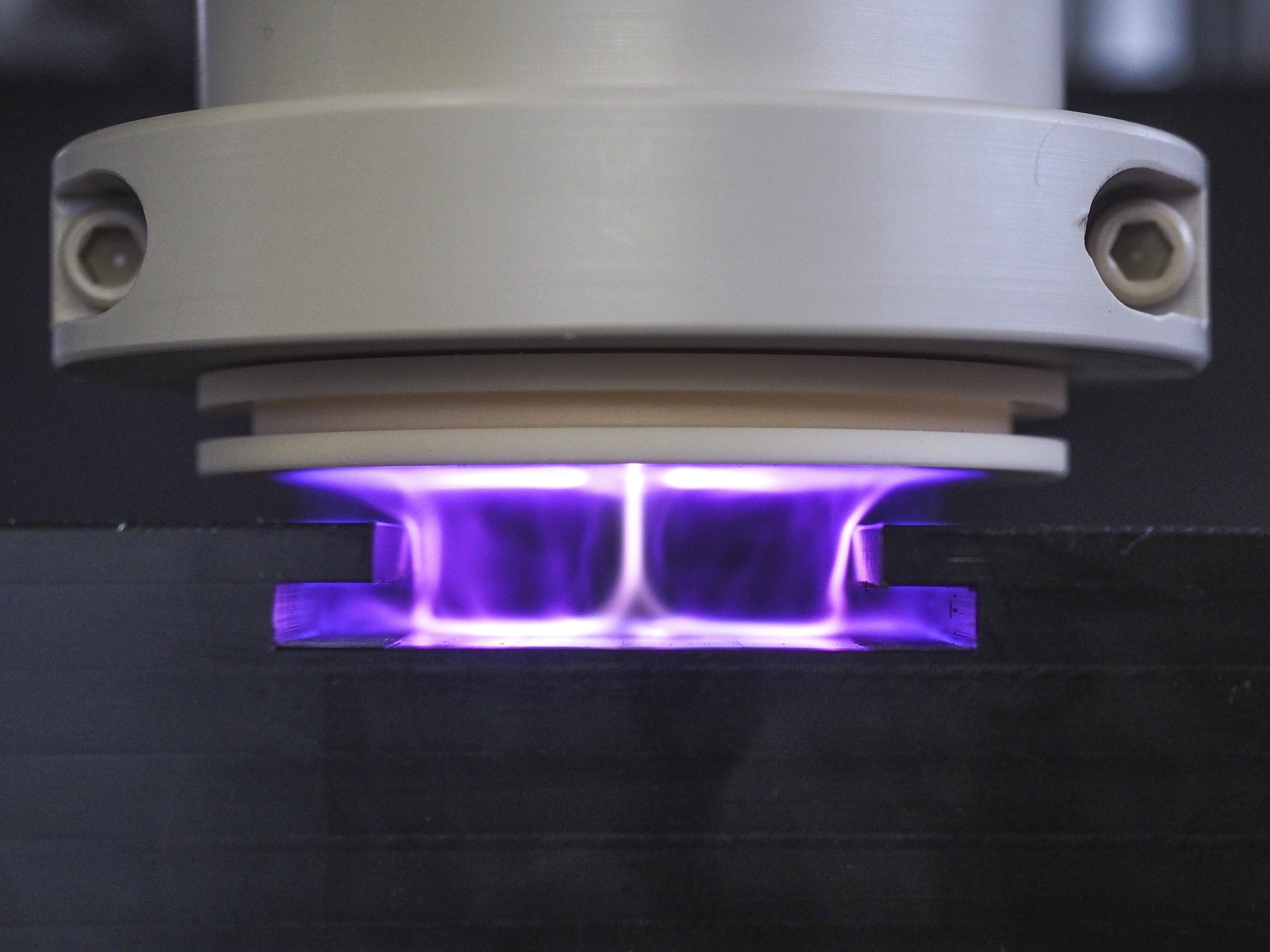

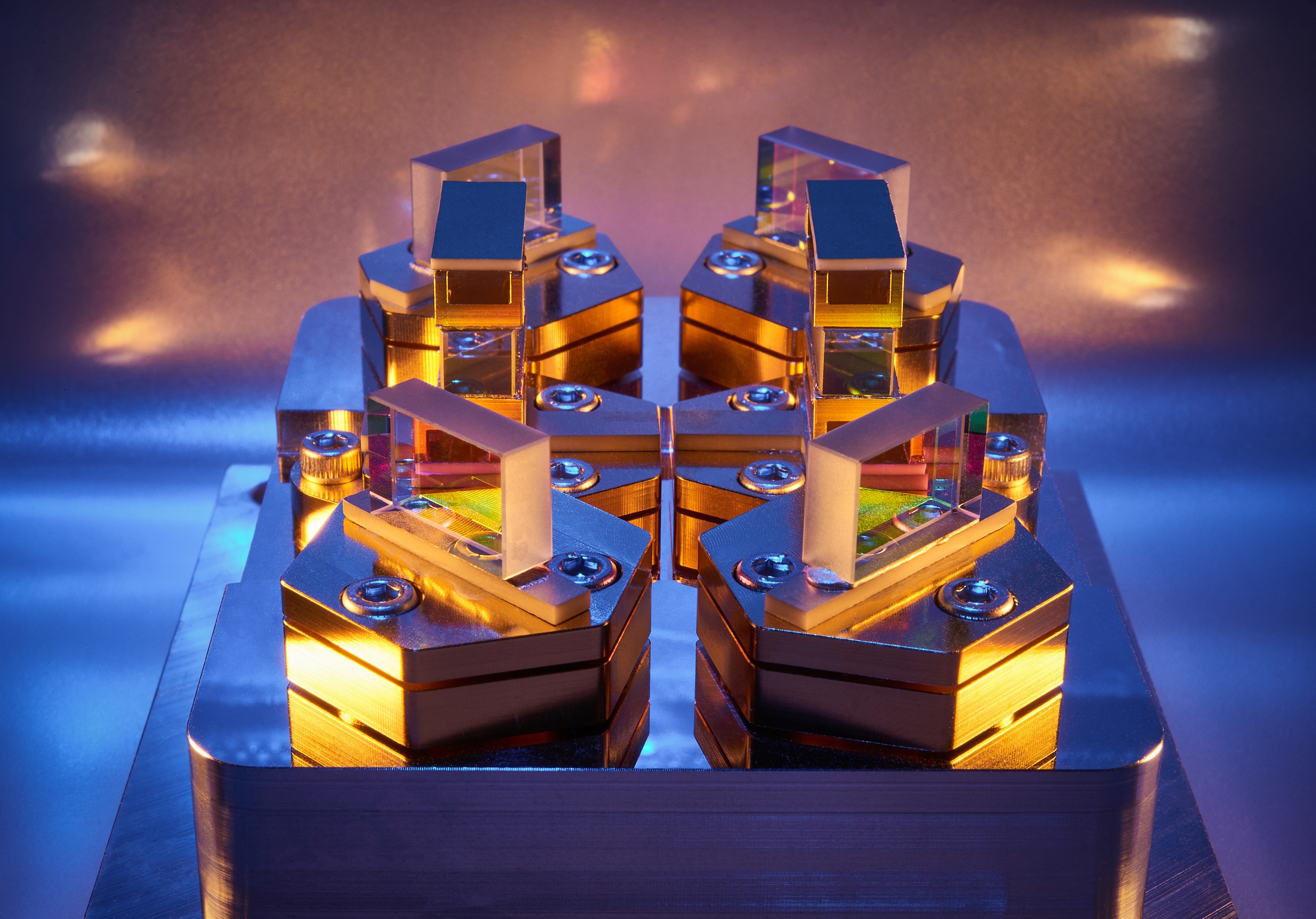

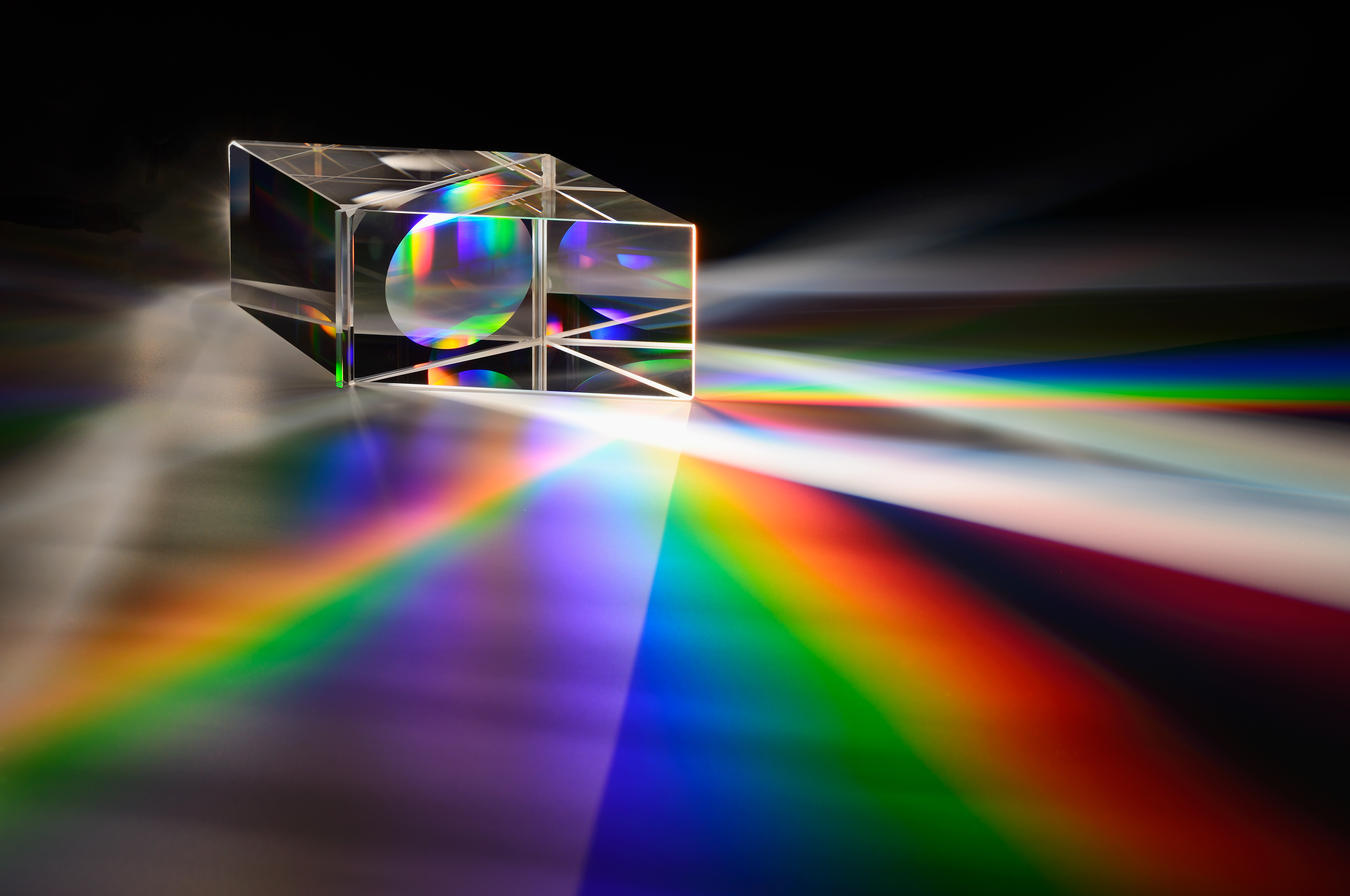

The Fraunhofer Group for Light & Surfaces combines Fraunhofer institutes that cooperate in the fields of lasers, optics, metrology and coating technology. The institutes combine complementary skills in the following areas: laser manufacturing techniques, beam sources, metrology, medicine and life sciences, optical systems and optics manufacturing, EUV technology, process and system simulation, materials technology, micro- and nanotechnologies, and thin-film, plasma and electron beam technology.

Competency by networking

Building on their basic research in the various fields of application, the institutes work together to supply fast, flexible and customer-specific system solutions in the fields of coating technology and photonics. Strategy is coordinated to reflect current market requirements, yielding synergies that benefit the customer. The institutes also collaborate with their local universities to provide the full range of student education, up to and including doctoral studies. As a result, the Fraunhofer institutes are not only partners to technological development, but also a continuous source of new talent in the fields of coating technology and photonics.

Core competencies of the Fraunhofer Group for Light & Surfaces

The Fraunhofer institutes' competencies are coordinated to ensure that research can be quickly and flexibly adapted to the requirements of the various fileds of application: optical and photonic components and systems, coating and surface treatment, measurement and inspection technology, manufacturing technology, and quantum technology.

Fields of application

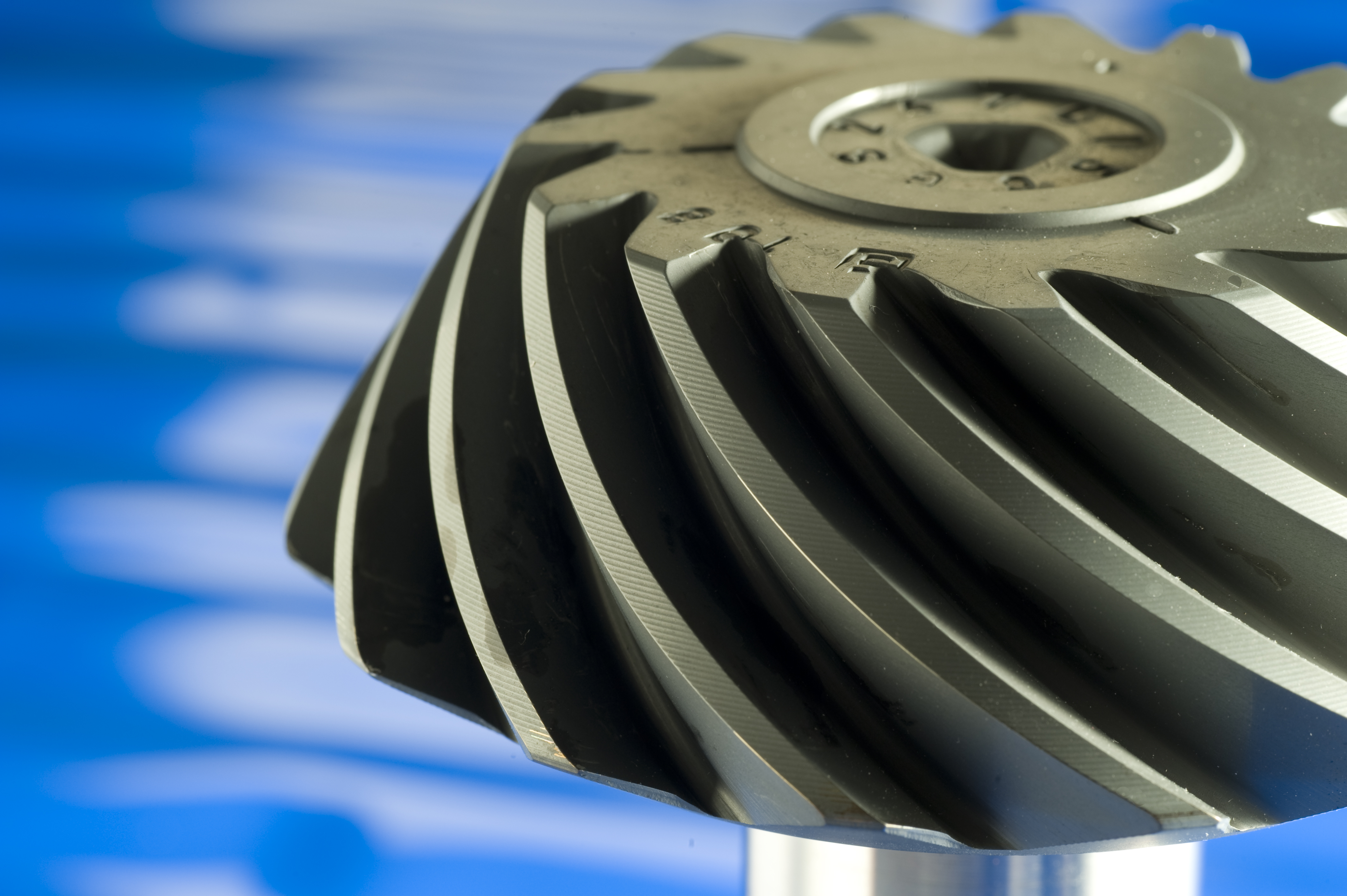

The Fraunhofer institutes are able to draw on extensive process expertise to provide customers with tailored, laser- and process-specific solutions that take material and product design, construction, means of production and quality assurance into account. These solutions serve a wide range of industries: automotive, biotechnology and life sciences, electronics and sensor technology, energy and the environment, aerospace, mechanical and plant engineering, tool and die manufacturing, optics.