As miniaturized probes and optics are developed and adapted to requirements for specific applications, novel measuring methods have been advanced with which spectroscopic information can be acquired in chemical or biotechnological processes. For example, light-scattering methods can be used to determine particle sizes between one nanometer and many micrometers. New developments make these analytical methods capable of working in-line, so they can be used for real-time process monitoring.

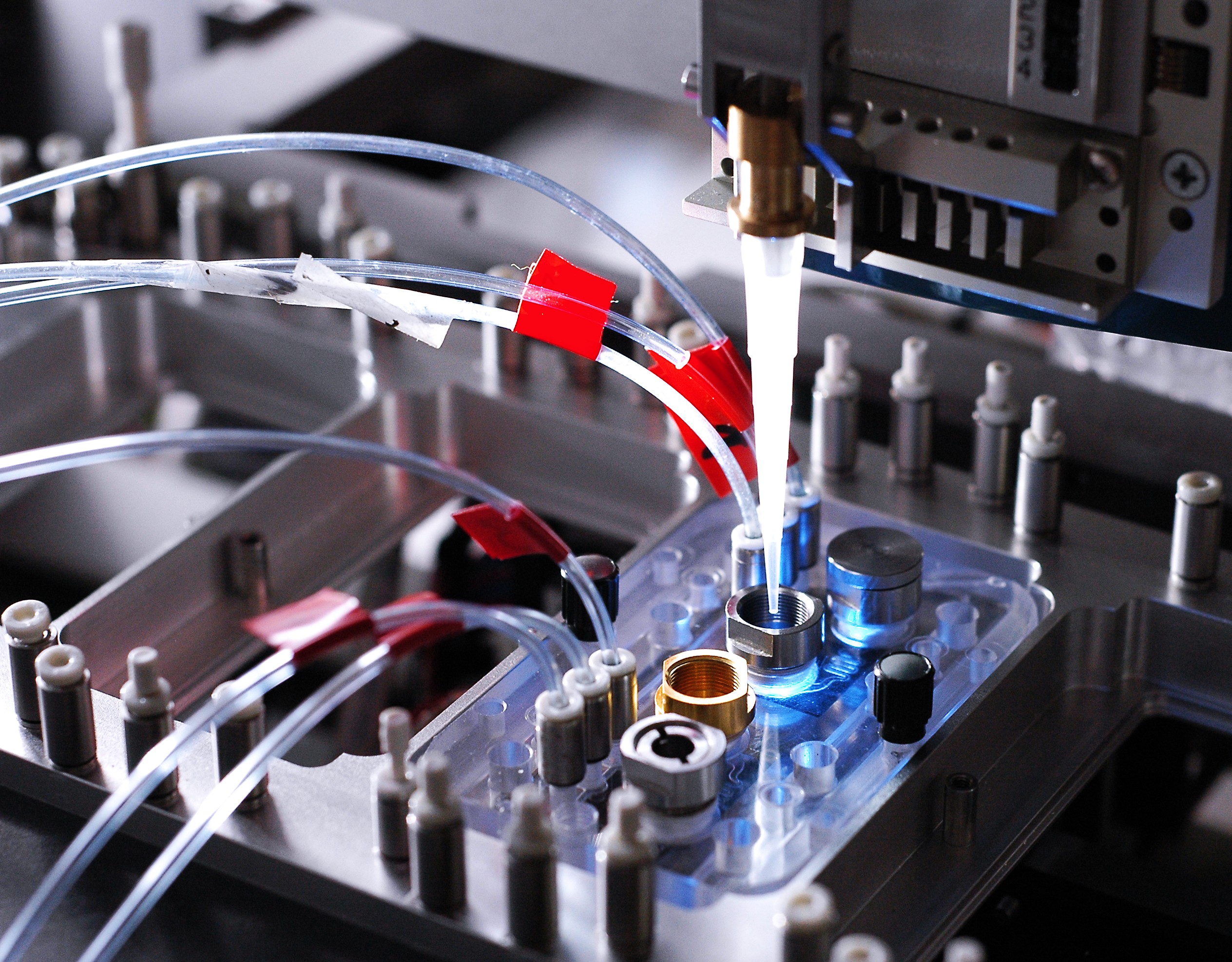

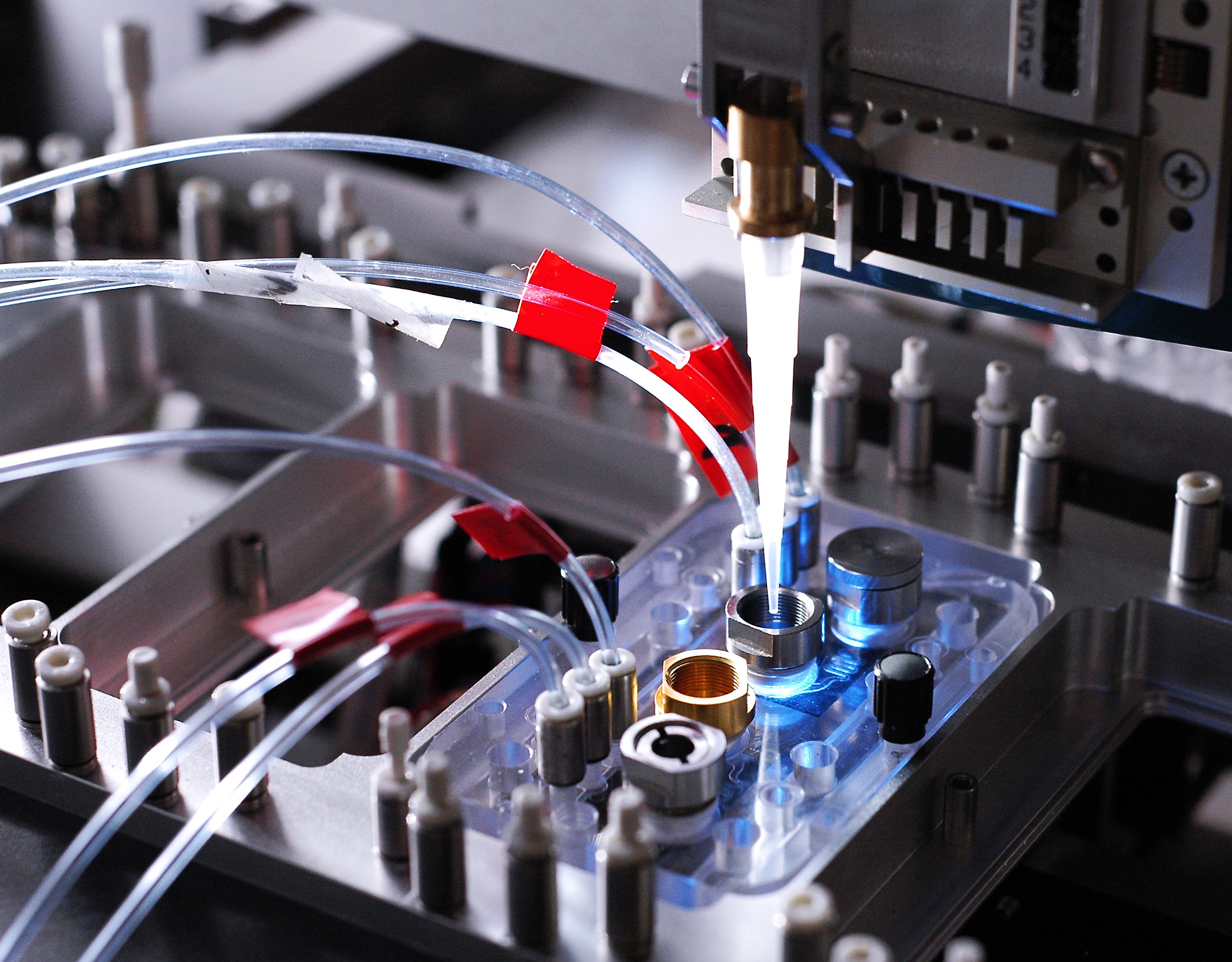

With special lab-on-chip systems developed at Fraunhofer IWS, medical applications such as, for example, organ-on-a-chip as well as technical issues on biosystems can be covered. The main focus of the work is as follows:

- Developing, designing and manufacturing lab-on-a-chip systems for in vitro testing,

- Developing automated measurement systems for the assembly, monitoring, supply and analysis of lab-on-a-chip systems,

- Developing, integrating and optimizing optical measurement technologies for lab-on-a-chip systems and

- Characterizing analyte-ligand interactions by means of surface plasmon resonance (SPR) technology (e.g. protein-protein, antigen-antibody, DNA-DNA and RNA-DNA).

In addition to measurement-related issues, the institutes can also provide technologies for the production of components and substrates for biotechnology. Fraunhofer IST, for example, is developing novel technologies for the plasma-functionalization of microfluidic systems. Microplasmas are plasmas which have a spatial extension of up to a few tens of micrometers. By applying microplasmas, the institute is able to selectively adapt surfaces to the desired application or even to coat the already covered channels of microfluidic components. In addition to changes in wettability, which can be exploited, for example, in the field of microfluidics, surfaces that have chemically functional groups can be specifically applied at particular locations. This way, they provide a basis for further coupling reactions for diagnostic detection systems.