To master multiple, individually-weighted requirements (cost, resources, quality, productivity) for the design of a process chain, research needs to use virtual tools, e.g. metamodels. A metamodel is the mathematical linkage of data from experiments and simulations; it indicates the multidimensional correlation of relevant parameters and criteria. Metamodels are a path to multi-critical optimization and a model-based predictive control of machines. With them, the institutes can offer customers the greatest possible overview of the parameter dependencies and limits of interlinked processes and their optimization.

A current example can be found in additive manufacturing. This process allows users greater freedom in designing real products and tailoring their functionality, both of which open up component design, also with regard to upstream and downstream steps in a process chain. The institutes develop integrated and end-to-end design tools and data chains or standards in order to intelligently design process chains and component functions.

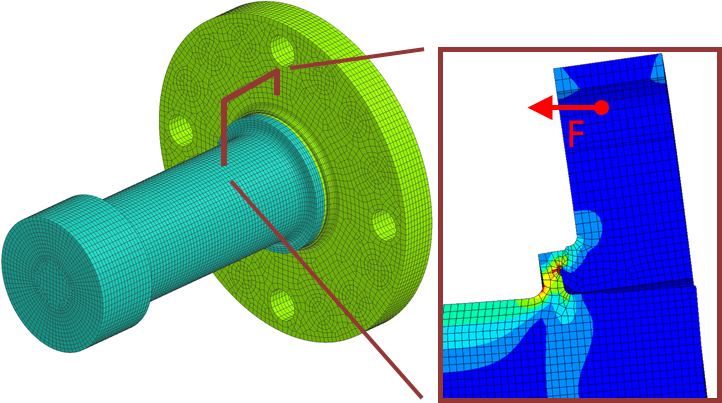

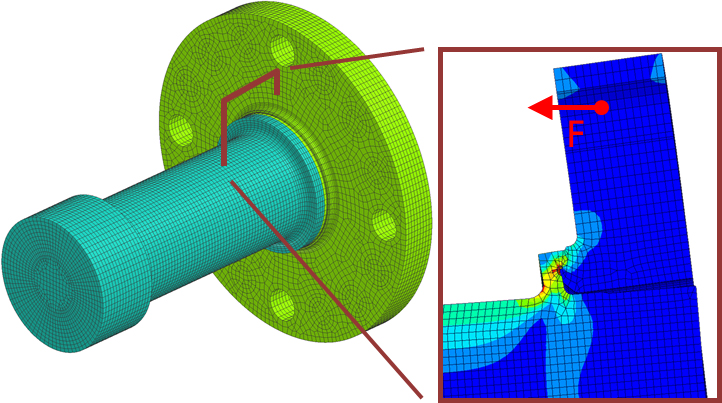

Increased component requirements, innovative materials or material combinations, as well as novel production processes generally also require new constructive approaches. To successfully implement the processes the institutes develop – in particular, various laser beam welding and heat treatment technologies – they advance process-oriented and load-adapted component design. The group works out solutions in close collaboration with renowned process development and materials science institutes.

Analogous to how it designs process chains, Fraunhofer IOF applies the same procedures for optical components. Fraunhofer IOF designs mechanical and optical systems that meet the final requirements and designs of the components or systems. In many cases, the data is fed back into a closed process chain between design, production and measurement in order to achieve the best possible results.