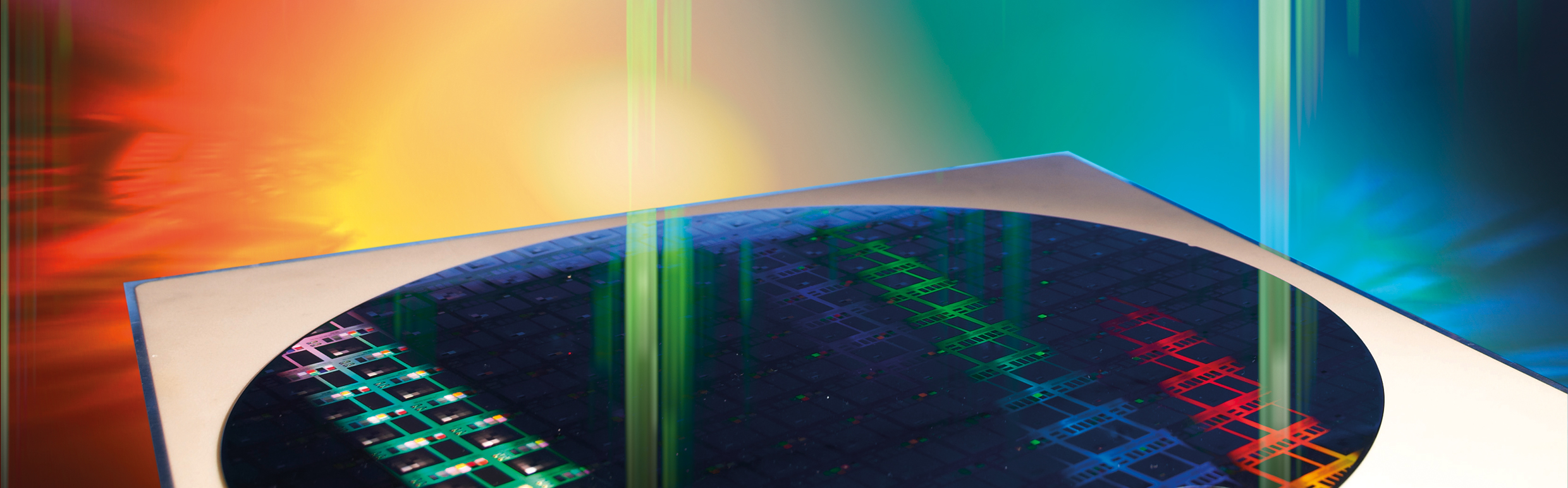

Fraunhofer Institute for Material and Beam Technology IWS

laser hardening

The business areas joining, cutting and surface technology are the main foci of the Fraunhofer Institute for Material and Beam Technology IWS. The research and development activities base on a distinctive know-how in the field of material engineering and nanotechnology and include the possibility of material characterization. The IWS`s special feature is its expertise in combining its know-how with its extensive experience in developing system technologies within the field of film- and laser technology.