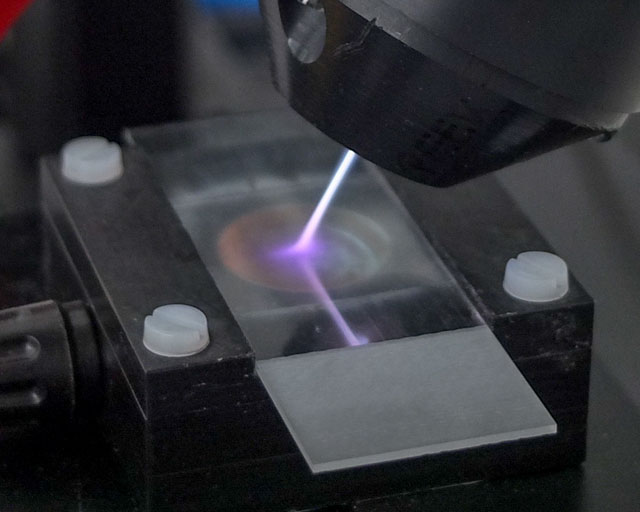

Plasma technology is an important tool in the production, modification and functionalization of coating processes and surface technology. The institutes of the Fraunhofer Group for Light & Surfaces use this technology both in coating processes to produce special layer functions and to modify laser-produced layers. When suitable excitation techniques are used in the gas phase, layer compositions and surface conditions can be selectively modified and adapted to the respective application. Atmospheric pressure plasma processes, for example, are widely used in the industry to clean surfaces as well as to activate polymers, metals, ceramics and other materials to improve their surface properties.

Coating processes at atmospheric pressure, when supplemented by additional plasma processes, can be used to selectively control wettability and surface tensioning with which hydrophilic, hydrophobic and even super hydrophobic surfaces can be generated.

Plasma-activated high-rate evaporation and plasma-enhanced chemical vapor deposition (PECVD) are two core technologies that the group’s institutes develop. High-rate PECVD is an established process that can deposit silicon-based polymer layers for different applications. The economical vacuum coating process also requires high coating rates on large areas. The plasma-activated deposition is a suitable method to achieve good coating properties even at high rates.

In addition to these supporting processes, plasma processes are also used for medical applications and those that change an object's properties. Here, the high electron energy of the plasmas and the resulting UV radiation are used to activate or deactivate surfaces.