Gas and particle measurement technology

Fraunhofer IPM focuses on the following in gas and particle measurement technology:

IR spectroscopy: For example, Fraunhofer IPM has developed a fast IR-filter spectrometer for the test stand to dynamically measure hydrocarbons in passenger-car exhaust gas. The system measures the concentration of different exhaust gas components simultaneously with a time resolution of five milliseconds and thus can analyze and optimize dynamic processes in multi-stage catalytic converter systems.

Gas measurement technology: Various methods of spectroscopy – from UV to MIR – are used in gas measurement technology. Miniaturized gas sensors, system components and sensor systems are particularly suitable for certain applications. These include, for example, application-specific semiconductor gas sensors and colorimetric gas sensors as well as radiators that can be modulated for the medium infrared.

Particle measurement technology: Different methods are used depending on a customer’s needs. Spectroscopic and microscopic methods are available in addition to scattered-light measurement methods for the rapid determination of particle size distributions – if appropriate, in combination with fluorescence measurement processes for the differentiation of particles.

Thin-film metrology technology

When complex optical layer systems are deposited, the thicknesses of the individual layers are of enormous importance. To account for this, Fraunhofer IST has developed the modular monitoring system MOCCA+® – innovative hardware and software that monitor and fully automate coating systems to produce (precise) optical systems. In this case, the transmission or reflection is measured in-situ at a wide spectral range from UV to SWIR, i.e. of wavelengths of up to approx. 2500 nm.

Laser-diode spectroscopy makes it possible to reliably detect the water vapor transmission rate (WVTR) of flexible ultra-barrier systems in the range of 10-6 grams per square meter and day. The new detection concept developed by Fraunhofer IWS, which combines a number of advantages, has been implemented as a compact laboratory device.

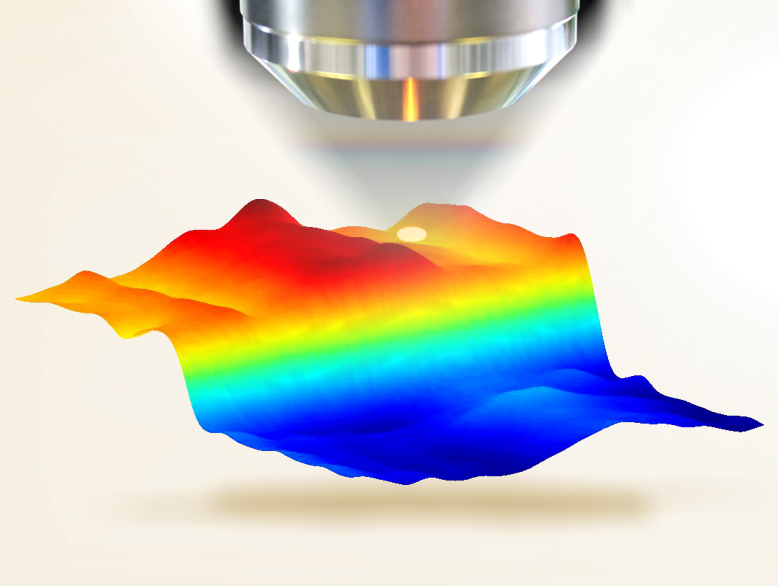

Moreover, hyperspectral imaging (HSI) provides spectroscopic imaging in the near infrared (NIR), visible (VIS) or ultraviolet (UV) range of the light, and allows a temporally or spatially resolved measurement of all spectral features. This way, the product or process can be analyzed both comprehensively and completely (100 percent). When the process is coupled with a microscope, the investigations extend down to the submicrometer range.

Processing and interpreting the data obtained are essential prerequisites for making measurements of high specificity. For this purpose, the Data Management Competence Center offers appropriate tools in cooperation with the Technische Universität Dresden and Dresden University Hospital. Together, the partners develop interactive assistance systems and methods for large data sets (big data). They focus on digital image data, which are used for early detection, temperature measurement, diagnosis, therapy planning, therapy support or success monitoring. Research and development range from image acquisition, image processing, modeling and visualization to user interface and application design.

For the analysis of thin-film systems both in-situ and as a means of product control, various spectroscopic methods have been developed and qualified as a system. As a key competency, Fraunhofer FEP provides systems to analyze chemical compositions:

- Optical glow-discharge spectrometry (GD-OES)

Hyperspectral Imaging

In addition, the Fraunhofer IWS offers hyperspectral imaging (HSI) spectroscopic imaging in the near infrared (NIR), visible range (VIS) or ultraviolet (UV) range of light and enables a time- or spatially resolved measurement of all spectral features. This allows a full and complete (100 percent) analysis of the product or process. The possibility of microscope coupling extends the investigations down to the sub-micron range.

The processing and interpretation of the data obtained is an essential prerequisite for a measurement of high specificity. To this end, for example, the Competence Center Data Management in cooperation with the TU Dresden and the University Hospital Dresden offers appropriate tools. Together, the partners develop interactive assistance systems and methods for large amounts of data (BigData). The focus is on digital image data that is used for early detection, temperature measurement, diagnosis, therapy planning, therapy support or performance control. Research and development ranges from image acquisition, image processing, modeling and visualization to user interface and application design.