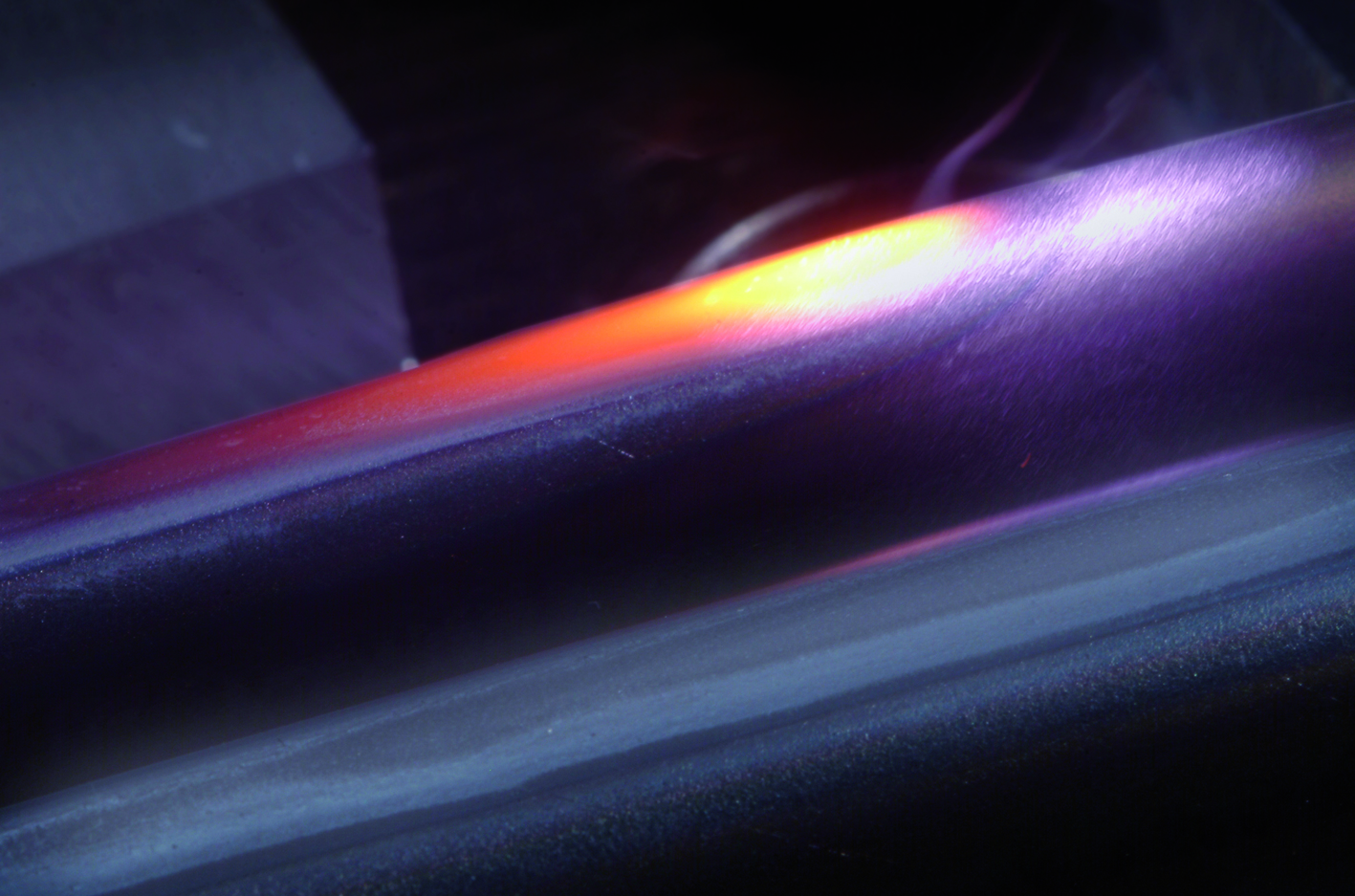

In the field of heat treatment, the Fraunhofer ILT are investigating processes for the post-treatment of high-strength steels to make them easier to form. In addition, the institutes are focusing on local heat treatment processes; laser irradiation is used to heat the material locally to a temperature below the melting temperature. Depending on the wall thickness, only one edge layer or the entire cross-section (e.g. in the case of a sheet metal) is briefly heated. The heating rate, the maximum temperature and the cooling rate can be adjusted by a temperature control. Applications for metallic materials can be found in the edge hardening of components made of hardenable steel or cast iron, the softening of high-strength steels, the recrystallization of thin sheets and the stress-relieving of additively manufactured components. In the field of non-metallic materials, the group also looks at the crystallization of silicon layers as well as the annealing of transparent, conductive materials.

Laser and Plasma Coating

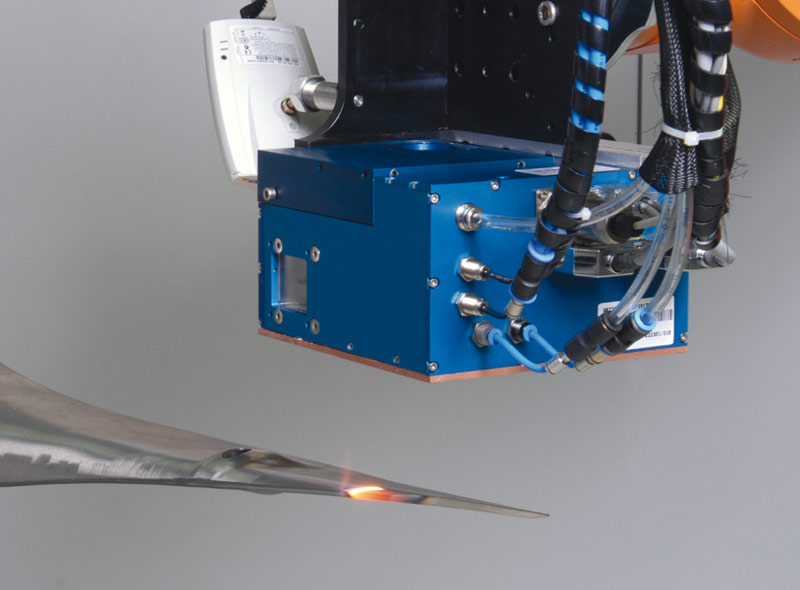

Laser coating processes often offer many new approaches to produce wear-resistant surfaces for component geometries and materials subject to great wear in which conventional hardening technologies fail.

At its disposal, Fraunhofer IWS has atmospheric plasma spraying (APS) as well as high velocity oxygen fuel (HVOF) and high velocity air fuel (HVAF) spraying processes with powders and suspensions to thermally coat components made of steel, light metals, ceramics, concrete and other materials containing metals, hard metals and ceramics. The use of suspensions instead of coating powders promises to have several advantages, including the ability to directly use finely dispersed powders and, thus, to save the production of special starting powders, but also the production of nanostructured layers. In addition, the group is examining the possibilities of producing thermally sprayed layers with a layer thickness below 100 μm. This could help to close the gap in the film thickness between CVD/PVD and conventional coating layers.

Laser Functionalization

For the functionalization of surfaces, Fraunhofer ILT uses various laser processes for micro- and macro-functionalization. In addition, it applies coatings having a thickness from 1 μm to several millimeters. In the case of thin layers, the application is first carried out by a printing process, followed by laser functionalization; in the case of thicker layers, the addition is directly applied in the form of wire or powder. Coating materials are metals, metal-based composites, for thin layers also ceramics and glass. Layer composites can also be applied.

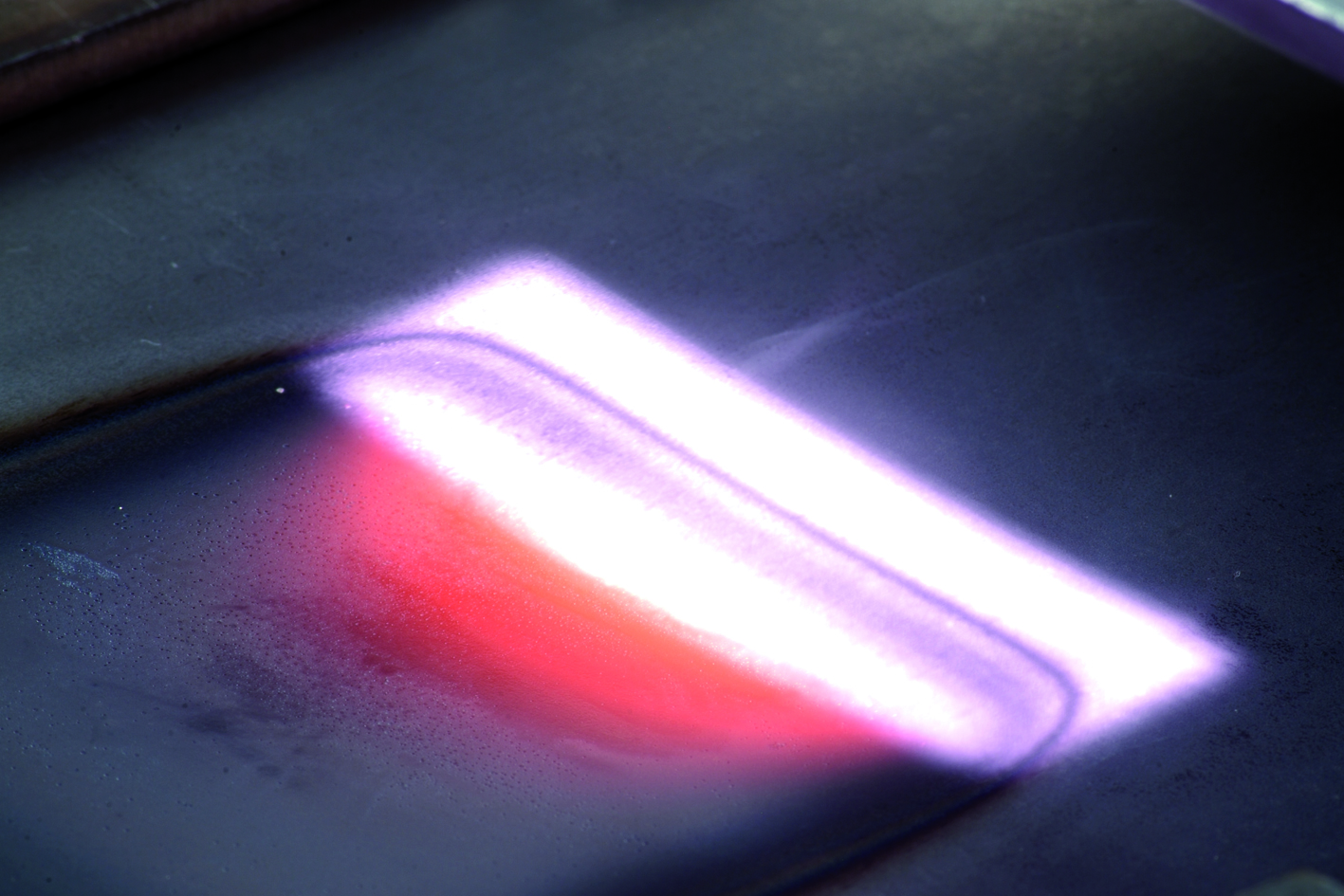

Fraunhofer IST uses the laser functionalization as post-processing for surfaces produced by means of cold plasma spraying. In this process, the coating is applied with a plasma jet into which various solutions, dispersions or (sub-) micropowder are fed. Through the special plasma generation, thermally sensitive substrates and natural materials can also be coated.

Fraunhofer IWS provides new methods and industrial systems to produce two- and three-dimensional micro- and nanostructures on polymers, metals, ceramics and coatings. In addition to the topography, the electrical, chemical and mechanical properties can also be varied periodically.