To develop technologies for machining processes successfully, research needs to conduct a detailed analysis of the processing results as well as a comprehensive characterization of the initial conditions and material interrelationships. All institutes of the Fraunhofer Group for Light & Surfaces have suitable measuring and material examination methods to accomplish this.

The institutes have developed a wide spectrum of materials arising from the various processing methods. In addition to this, they also have characterized, in detail, materials and processing results, e.g. through the chemical analysis of materials (spatially resolved, deep-resolved, near-surface or average), through X-ray spectroscopy (EDX/WDX/EPMA), secondary ion mass spectroscopy (SIMS), photoelectron spectroscopy (XPS) and X-ray fluorescence analysis (RFA/XRF). For example, they are developing new thermoelectric materials which are used for energy harvesting or biocompatible materials and can be produced additively. Particularly thanks to special thin-film processes, new tribological layers can be produced as can optically active materials, which are used as OLED components.

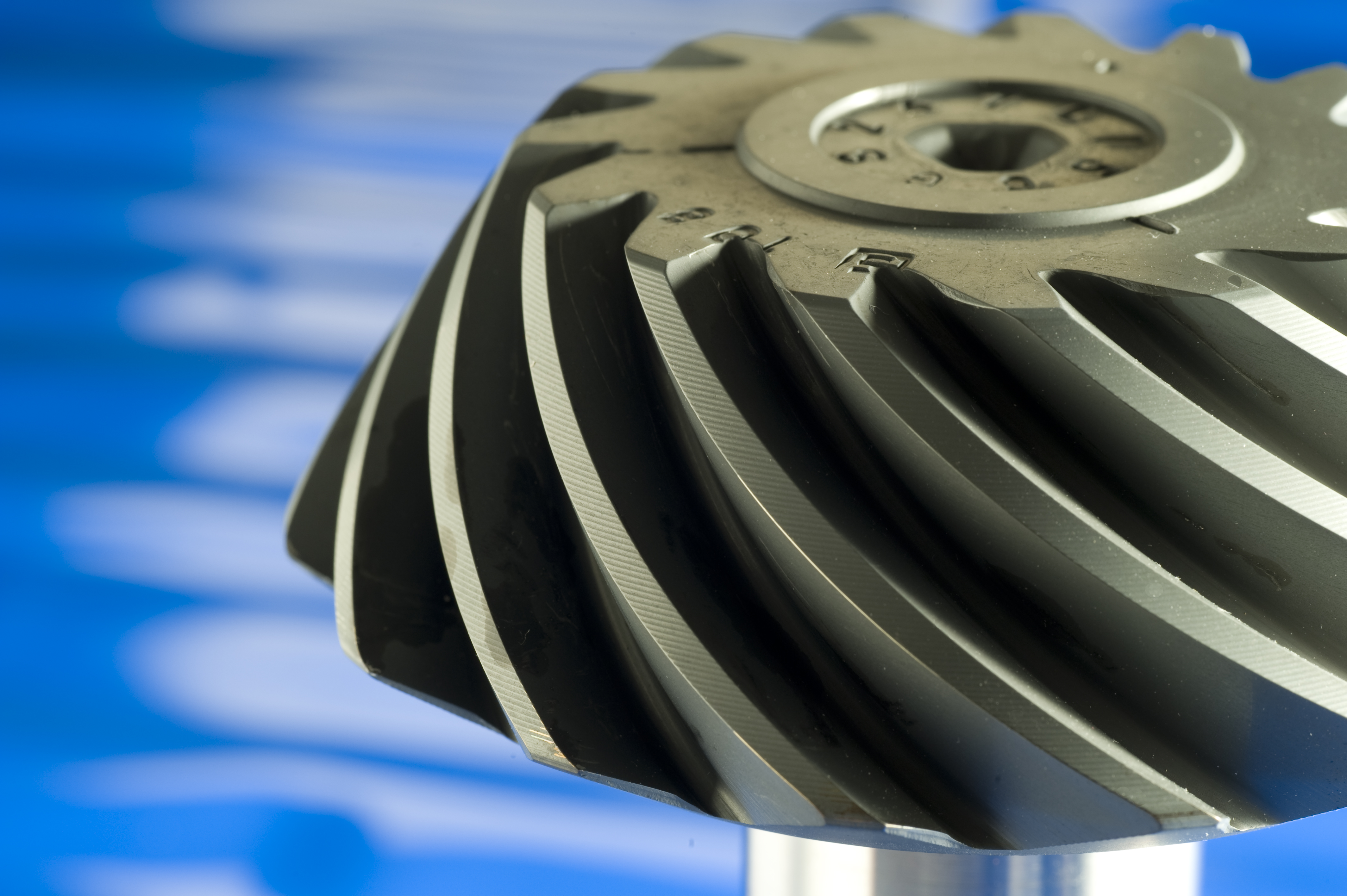

Moreover, the group’s institutes use a large number of application-specific test methods to characterize material properties, e.g. hardness, friction, wear, corrosion, or fatigue behavior.

In addition to conducting material investigations, the institutes can also carry out functional investigations on components. The services they offer ranges from determining mechanical properties of materials and material combinations, establishing characteristic curves to assess vibration resistance and, in particular, conducting time-shortened fatigue tests at high test frequencies, all the way to analytically characterizing laser-modified edge zones, joining interfaces, thin film systems, nanotubes and nanoparticles all in high-resolution images.