12-13th of September 2018

“3rd Conference on Laser Polishing – LaP 2018” Attracts International Experts and Users

The “Conference on Laser Polishing – LaP” at the Fraunhofer Institute for Laser Technology ILT is an international meeting point for all experts using or researching laser polishing. For the third time, the conference took place in Aachen and offered a comprehensive overview of research results and trends relating to the industrial use of laser polishing for metals, glass and plastics. On September 12 and 13, some 80 participants from a total of 15 different countries exchanged knowledge as well as ideas and gained insights into the laboratories at Fraunhofer ILT.

Laser polishing processes can be used in many different applications and combinations, for example in machining micro-structured metal surfaces and complex optical glass surfaces or for post-processing of additively manufactured parts. Key areas of use currently include toolmaking, precision mechanics and medical engineering.

The “3rd Conference on Laser Polishing – LaP 2018” featured a total of 20 speakers from a number of European countries as well as the US, Canada, India and China. The experts presented research results for laser polishing of different types of metal and glass. For the first time, two of the presentations examined also the laser polishing of plastics, with a specific focus on additively manufactured parts.

From scientific research to industrial use

Professor Frank Pfefferkorn from the University of Wisconsin, USA, kicked off the event with a comprehensive introduction to the fundamental principles and applications of laser polishing. A feasibility study based on the example of polishing marine propeller blades was presented by Brodan Richter, also from the Department of Mechanical Engineering at the University of Wisconsin.

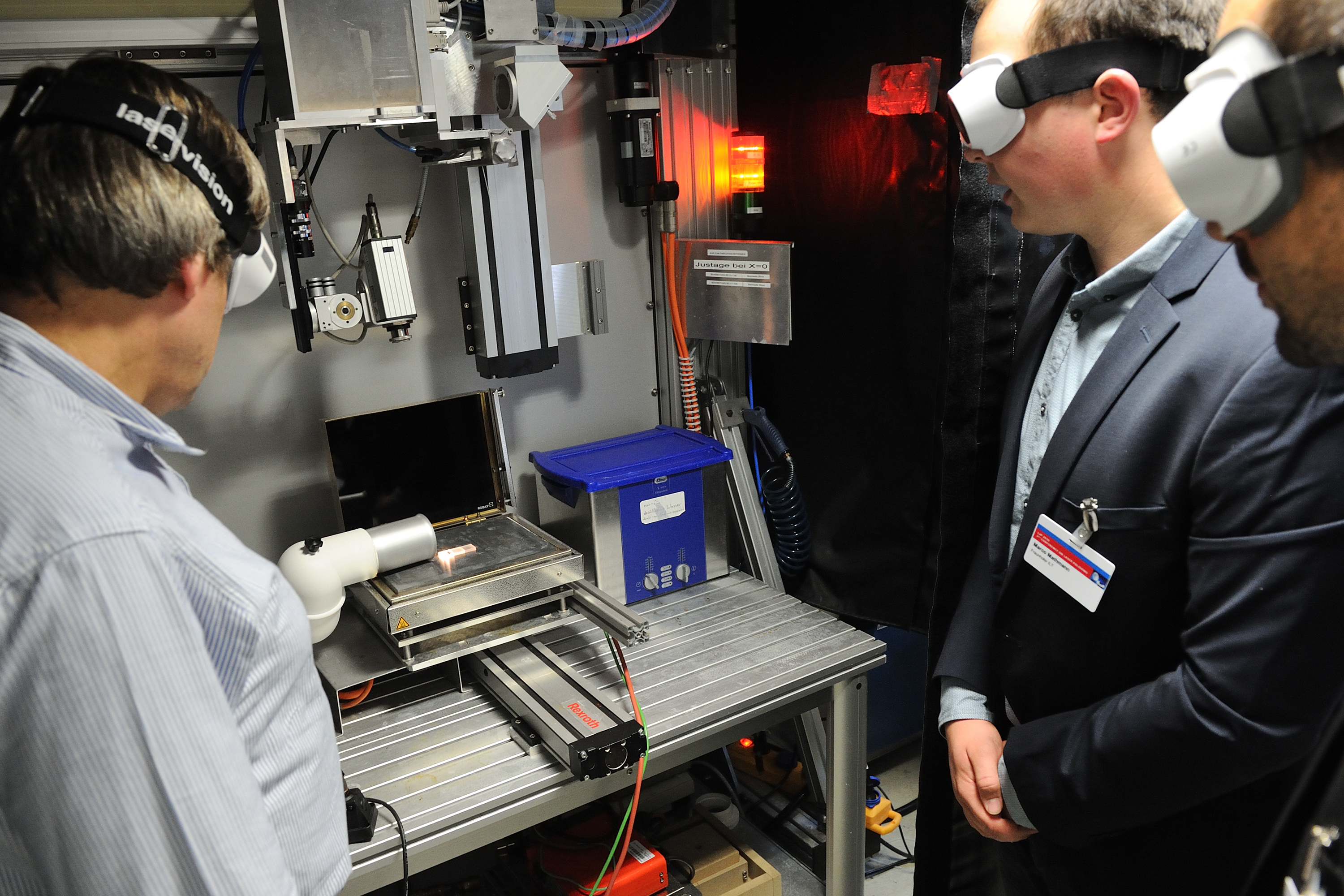

The Ravensburg-based company Maschinenfabrik Arnold showcased the first industrial-scale laser polishing machine for metal workpieces, initially as part of their presentation and subsequently in the lab at Fraunhofer ILT. The machine’s five axes make it a suitable choice for polishing complex 3D workpieces. It uses a CAM-NC data chain to efficiently program the polishing process. On the laboratory tour, scientists from Fraunhofer ILT also gave live demonstrations of various laser polishing processes and presented a range of laser-polished metal, glass and plastic parts.

The “Conference on Laser Polishing – LaP” provides an excellent opportunity for laser polishing experts to meet and share experiences and visions. The next edition will take place at Fraunhofer ILT in Aachen in 2020.

- More information on Laser Manufacturing (light-and-surfaces.fraunhofer.de)

- Further information on LaP 2018 (ilt.fraunhofer.de)

- For more information please visit Fraunhofer Institute for Laser Technology ILT (ilt.fraunhofer.de)