Plasmas are a versatile tool in coating technology, surface activation, cleaning and functional structuring. The institutes of the Group for Light & Surfaces not only develop applications for plasma technology, but also the system components needed for them.

Plasmaquellenentwicklung

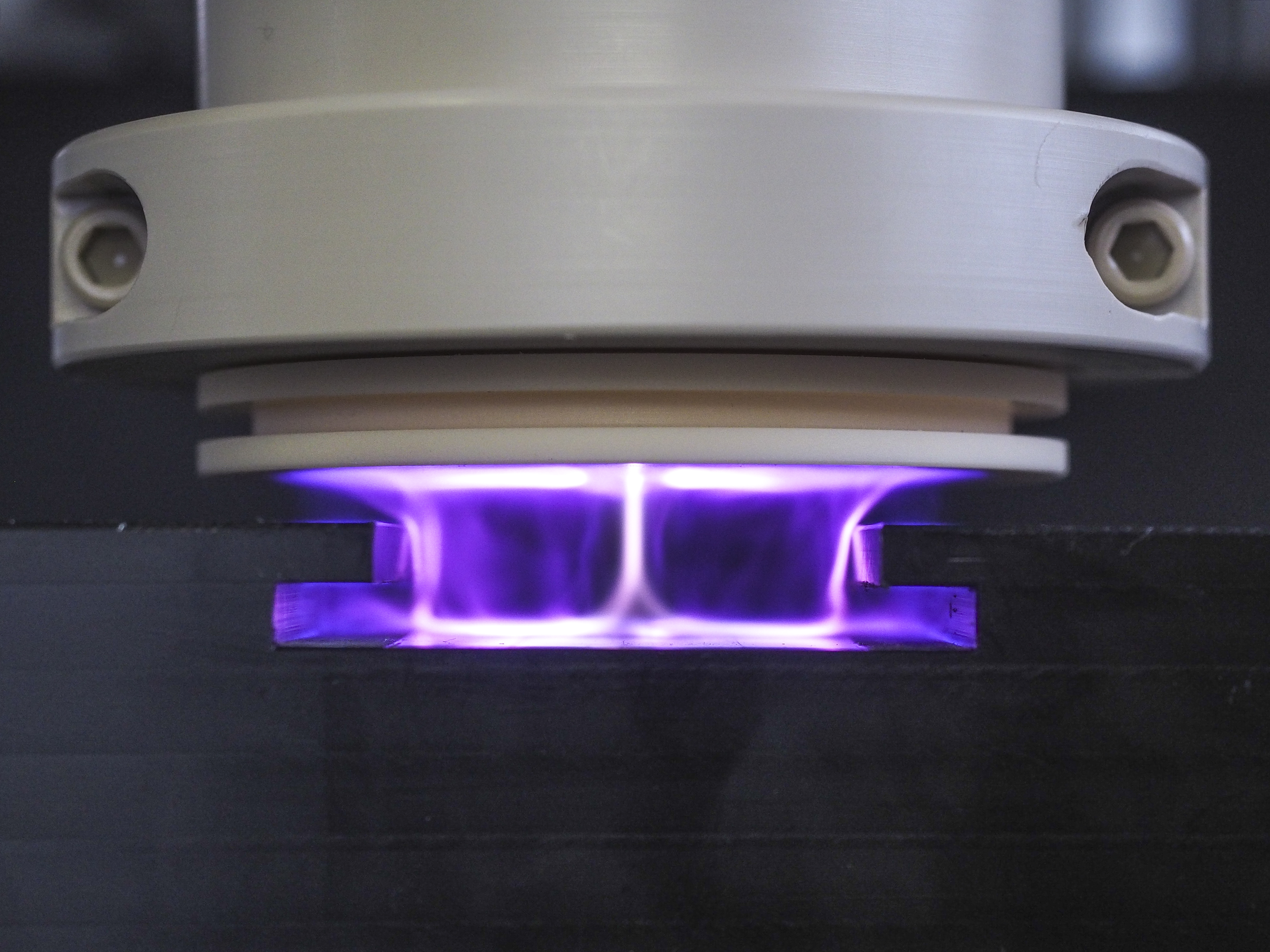

Fraunhofer IST is developing and investigating new and specialized plasma sources for industrial applications, especially for surface activation and coating, fine surface cleaning, application of functional groups, biological-medical sterilization and plasma diffusion. The physical basis is provided by low-pressure glow discharges and dielectrically impeded discharges at atmospheric pressure. Fraunhofer IST has considerable expertise in the production of sources and equipment, their production technology, as well as for plasma diagnostics and simulation.

Coating technology

Plasma technology is an important component for applications in coating technology since, above all, the quality of the coating can be controlled while retaining high productivity. So that vacuum coating can become economical, it must be able to coat large surfaces at high coating rates. The path to ever higher coating rates, particularly in the case of high-rate evaporation, is made more difficult in that the layers growing at high rates have a pronounced columnar structure. For the bond formation of reactive vapor deposition to occur, the energy of the vapor particles is often insufficient for a stoichiometric deposition of oxide, nitride or carbide layers. A suitable way to increase the particle energy is by activating the plasma during evaporation. This requires powerful sources for dense plasmas, which are adapted to both a high coating rate and large-area coating. Fraunhofer FEP has developed processes based on the combination of high-rate evaporation with different guided arc discharges (SAD and HAD process). For this, the institute offers the following development services:

- Development of the coating process and the coating system for your product

- Development and delivery of key modules (evaporators, plasma sources)

- In-situ quality control and process automation

- Plant technology and operator know-how for plasma-activated evaporation plants

Plasma and reaction technology

In addition to developing individual components for plasma processes, the Fraunhofer institutes Fraunhofer IWS, Fraunhofer FEP and Fraunhofer IST also offer services in the field of plasma and reaction technology, including the development of tailor-made coating systems/prototyping according to customer requirements and comprehensive consideration of the system and process parameters. This encompasses:

- Fluid dynamic simulations

- Thermal and plasma-assisted deposition of functional layers (nm range)

- Thermal and plasma-assisted etching, fine cleaning, modification and structuring of surfaces (nm range)

- Process development and coating of samples