Hannover Messe 2019

Digital Solutions and new materials

Industry 4.0, digitization, simulation and modeling of materials, processes, product and production systems and even entire factories are topics, which become more and more important for the Fraunhofer Institute for Surface Engineering and Thin Films. As a result, the institute again attends the Fraunhofer booth „Digital Solutions & New Materials“ (Hall 6, Stand A30) at this year‘s Hannover Fair from April 1-5, 2019.

Our main topics at a glance:

Process simulation

The process simulation facilitates the development of precise and efficient processes in thin film technology. At the Hannover Messe the Fraunhofer IST presents a simulation environment for the description of plasma coating processes as well as a simulation of dust particles, which enables a prediction of dust contamination in plasma coating systems. Furthermore, a multi-scale simulation of production systems using the example of a battery factory line will pe presented.

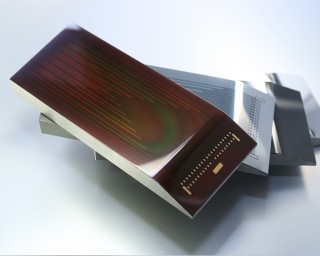

Sensory thin-film systems for measuring parameters in high-load areas of production plants

In the age of Industry 4.0 the production of the future should be able to meet ever increasing demands: processes should be flexible, intelligently networked and sustainable, the production facilities must work safely, intuitively and at the same time resource efficiently. Thin-film sensors developed at the Fraunhofer IST provide solutions that generate measurement data where measuring systems are difficult to integrate, e.g. in main load zones in direct contact between the workpiece and tool.

Cold plasma spraying

In cold plasma spraying, nano and micro particles are thermalized in a plasmajet and are directed to a substrate with the gas flow. Specific in this procedure is the possibility to homogeneously coat heat sensitive surfaces with materials such as copper and aluminum as well as with high-strength stainless steel or titanium. It is possible to generate electric conductive layers, blanks and patterns on substrates such as plastics, thin glass, foil and paper, as well as on three dimensional objects.

Wear resistant antifouling and antiadhesion coatings

The Fraunhofer IST has developed coatings for a number of application areas that reduce the effects of fouling considerably. The coatings reduce adhesion and, in addition, offer a high degree of wear and corrosion resistance.

Friction reduction and wear protection for motor components, mechanical parts and tools

DLC coatings can increase service life and load capacity and reduce friction losses. Such coatings are relevant whenever components move against each other. The Fraunhofer IST was significantly involved in developing the DLC coatings and keeps working intensively on the customization of various DLC modifications. The focus is particularly on combinations of different coatings and coating technologies.