Hannover Messe

Hannover Messe 2019: Ultralight metal mirrors through additive manufacturing processes

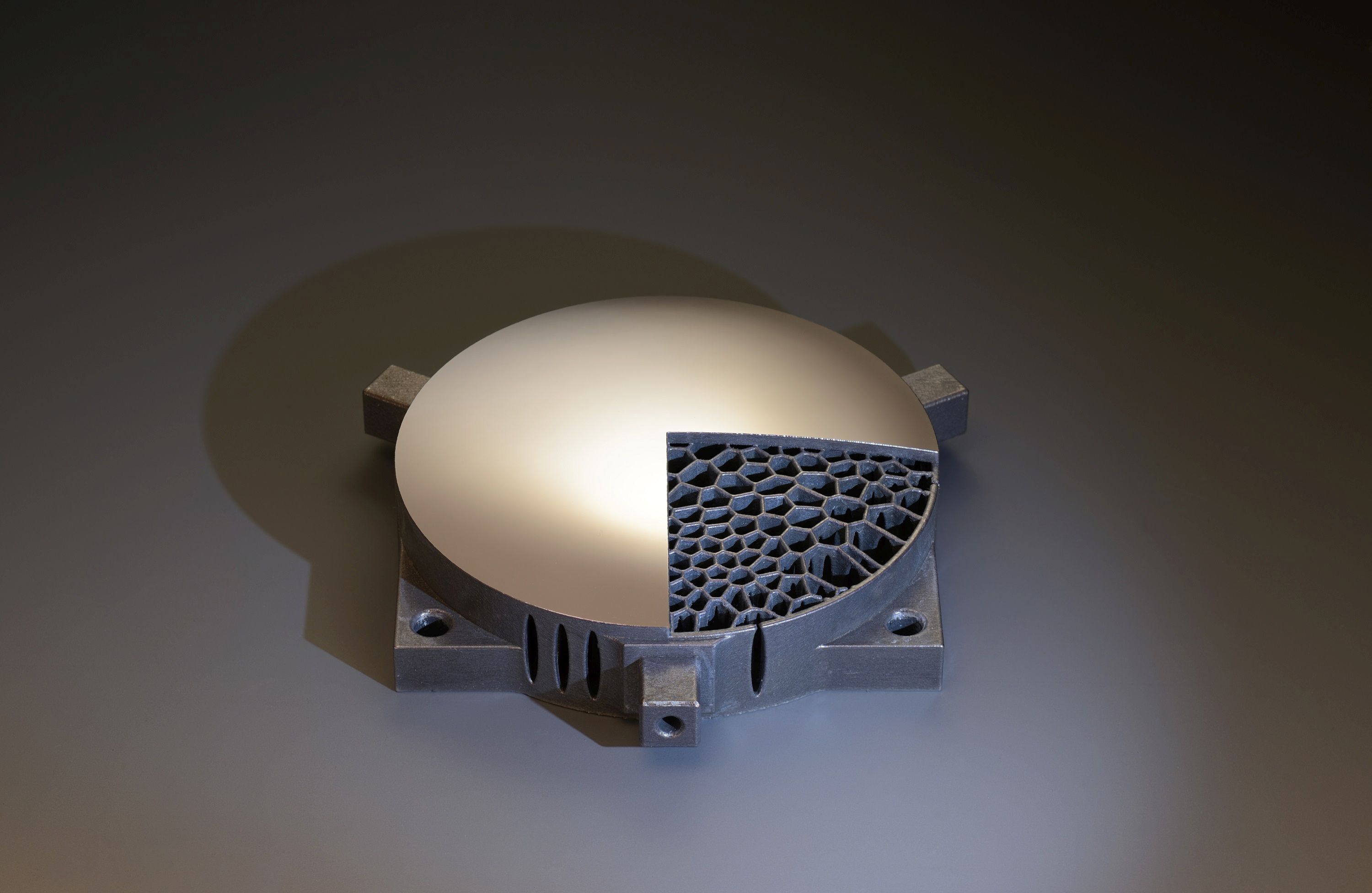

Scanner mirrors and space born telescope mirrors have one thing in common: Every gram counts. So these are typical cases for light-weight structures. Conventional techniques with back pockets and drilled structures allow for weight reductions of more than 30%. But a dedicated design and an additive manufacturing process enable weight reductions of more than 65%. The team from Fraunhofer IOF uses Selective Laser Melting to manufacture metal mirrors. Such an additive light metal mirror will be exhibited by the Fraunhofer Institute for Applied Optics and Precision Engineering IOF at this year's Hannover Messe from April 1st to 5th.

Ultralightweight metal mirror

Both space applications and fast moving scan systems require extreme lightweight components. The support structures of metal mirrors for these applications are manufactured by means of Additive Manufacturing or Selective Laser Melting and new materials. They show comparable or better mechanical properties than conventional solids at 60% weight savings. The finalization to the optical quality takes place by means of ultra-precision diamond processing. Additive production of metal mirrors saves up to 75% weight.

Due to the lightweight design with stochastic or symmetric structures, a mass reduction of up to 75% is achieved. Several materials have been qualified, such as AlSi12, AlSi40, and Al6061. Mirrors of 150 mm exhibit high stability and stiffness along with surface roughness of <1 nm RMS and form deviation of <150 nm PV after post finishing.

The advantages over conventional techniques such as drilling and milling are that components can be produced directly and flexibly from 3D CAD data. In addition, the process offers a high degree of design freedom and function integration.

The Fraunhofer Group for Light & Surfaces

Further information about the Hannover Messe 2019 and on the exhibits exhibited by the Fraunhofer Light & Surfaces Group can be received on a regular basis on our homepage under “Press & Events”.

The Fraunhofer Light & Surfaces Alliance brings together the expertise of six Fraunhofer Institutes. The institutes combine coordinated competencies in the fields of laser manufacturing processes, laser beam sources, measurement technology, medicine and life sciences, optical systems and optical manufacturing, EUV technology, process and system simulation, materials technology, micro- and nanotechnology, thin-film as well as plasma and electron beam technology.