LASER World of PHOTONICS

Fraunhofer: What’s next?

In the 70th year of its history, the Fraunhofer-Gesellschaft is ideally positioned for the challenges of the future, a strategy it also demonstrated at LASER World of PHOTONICS, the world's leading photonics trade fair in Munich. The Fraunhofer Institute for Laser Technology ILT, for example, presented state-of-the-art technology for quantum technologies, metallic 3D printing and electromobility.

From June 24 to 27, the laser community met for the trade fair in Munich, which has continued to grow since its inception. Thanks to around 34,000 visitors and 1325 exhibitors, LASER World of PHOTONICS set two new records in 2019.

The topics at the fair and the associated congress ranged from basic research on gravitational waves and new quantum detectors to industrial applications in which lasers enable energy-efficient processes for the manufacture of electric cars, for example.

Ultrafast lasers go on the offensive with kW systems

“The right lasers for the right applications” is how Prof. Reinhart Poprawe, outgoing director of Fraunhofer ILT, describes the credo of his institute. After 23 years at the helm of Fraunhofer ILT, he will retire this fall. The institute has focused on developing new beam sources and Poprawe has been very successful in helping them achieve milestones such as the Innoslab system. This also resulted in the Fraunhofer Cluster of Excellence Advanced Photon Sources CAPS for the development of ultrafast lasers with high average powers.

In this cluster, under the leadership of Fraunhofer ILT and IOF experts from 11 other Fraunhofer institutes are working on laser and process technology for the next generation of these innovative systems. “We want to combine the precision of the ultrafast laser with the surface throughput of modern cutting and welding lasers”, says Hans-Dieter Hoffmann from Fraunhofer ILT in Aachen, summarizing the strategy. Over the next few months, laboratories will be opened in Aachen and Jena where high-performance lasers with kW power will be available for application development.

Laser technology for e-mobility

“No e-mobility without laser technology” was an important motto of the laser trade fair: in Munich, the “eace05” electric racing car from the Ecurie Aix – Formula Student Team at RWTH Aachen University served to demonstrate how this motto could be put into practice. For the ultra-light body of the racing car, which weighs almost 180 kilograms, CFRP parts were laser-cut and the battery cells laser-welded. The engine and wheels contain parts produced from metal powder by a 3D laser printer. “Laser processes in e-mobility enable processes and product qualities that would be unthinkable otherwise”, explained Johanna Helm of Fraunhofer ILT.

At the booth, the Aachen engineers also demonstrated how battery cells can be welded with robot support. In this process, Laser-Based Tape-Automated Bonding (LaserTAB), they showed how robots, laser scanners and process monitoring work together. KuKa's sensitive lightweight robot also acquired a special ability: As an “intelligent industrial work assistant (iiwa)”, it can closely cooperate between humans and robots. Thanks to joint torque sensors, it recognizes contacts and immediately reduces force and speed.

Clever combi-head for three different laser processes

Today, lightweight construction and e-mobility are almost synonymous with the demands for more flexibility and efficiency. In a project with various industrial partners, the experts from Fraunhofer ILT analyzed how classical and future machining processes can be performed with just one laser head.

For the NRW-funded lighthouse project MultiPROmobil, a combi-head was developed that can not only cut and weld with the laser, but also generate additive layers. The project partners are currently working on optimizing the combi-head so that it can carry out all three processes in a production plant in a “flying change” – without having to change optics or nozzles. The project also developed simulation software that maps machines, processes and components using digital twins, thus enabling the process to be better controlled and optimized.

Factor 10 faster for additive processes

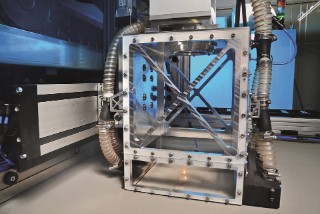

The additive manufacturing of metal components has great potential for completely new design solutions. However, one of the inhibiting factors for industrial use so far has been low productivity. This is why six Fraunhofer institutes joined forces in 2017 to form the Fraunhofer lighthouse project “futureAM – Next Generation Additive Manufacturing”, which aims to accelerate the additive manufacturing process for metal components (metal AM) by a factor of ten.

“Our work focuses on the entire process chain, from order processing through design and simulation to production in the machines”, explains Christian Tenbrock, a research associate at Fraunhofer ILT and project coordinator of futureAM. “This approach is very important for us, because integrated thinking is the actual core of the project”.

Building blocks for quantum technologies

Quantum technologies are currently being promoted internationally at a cost of billions. Here, we see ourselves at the beginning of the technical revolution that will enable fundamentally new applications. These include quantum imaging, quantum communication and quantum computing. For such processes to make their way into market-ready applications, however, highly integrated photonic components must become available. That is why Fraunhofer ILT is developing process technologies to produce waveguides, couplers and filters in glasses and crystals. High-power ultrafast laser systems serve as the basis.

“With the know-how built up over the past decades, we at Fraunhofer ILT can develop components and applications for quantum technologies in several projects”, says Florian Elsen, coordinator of quantum technologies at Fraunhofer ILT and who is looking forward to ongoing and upcoming projects. Among other things, he is currently working on processes for quantum imaging, but also on the optical interface for the quantum internet of the future.

The next LASER World of PHOTONICS will take place in Munich from June 21 to 24, 2021.

- More information on the Areas of Competence of Fraunhofer Group for Light & Surfaces

- For further information please visit Fraunhofer Institute for Laser Technology ILT (ilt.fraunhofer.de)

- More information on the Fraunhofer Cluster of Excellence Advanced Photon Sources CAPS (fraunhofer.de)

- More information on futureAM – Next Generation Additive Manufacturing (futuream.fraunhofer.de)