Hannover Messe 2018

Highly corrosion-resistant steels in additive manufacturing

In additive manufacturing, the material or powder composition is a focus topic. At the Fraunhofer Institute for Material and Beam Technology IWS Dresden, special materials such as highly corrosion-resistant steels and high-temperature-resistant nickel-based alloys are qualified for selective laser melting in addition to widely used materials.

By adapting the material combination and the design of the process parameters, the scientists optimize the energy input into the powder bed to such an extent that almost complete pore-free components are produced. The component strengths are comparable with those of the base materials and can even exceed their strengths in the direction of construction. The use of these materials makes it possible to establish additive manufacturing processes in the high-tech sector, for example in aviation-oriented applications.

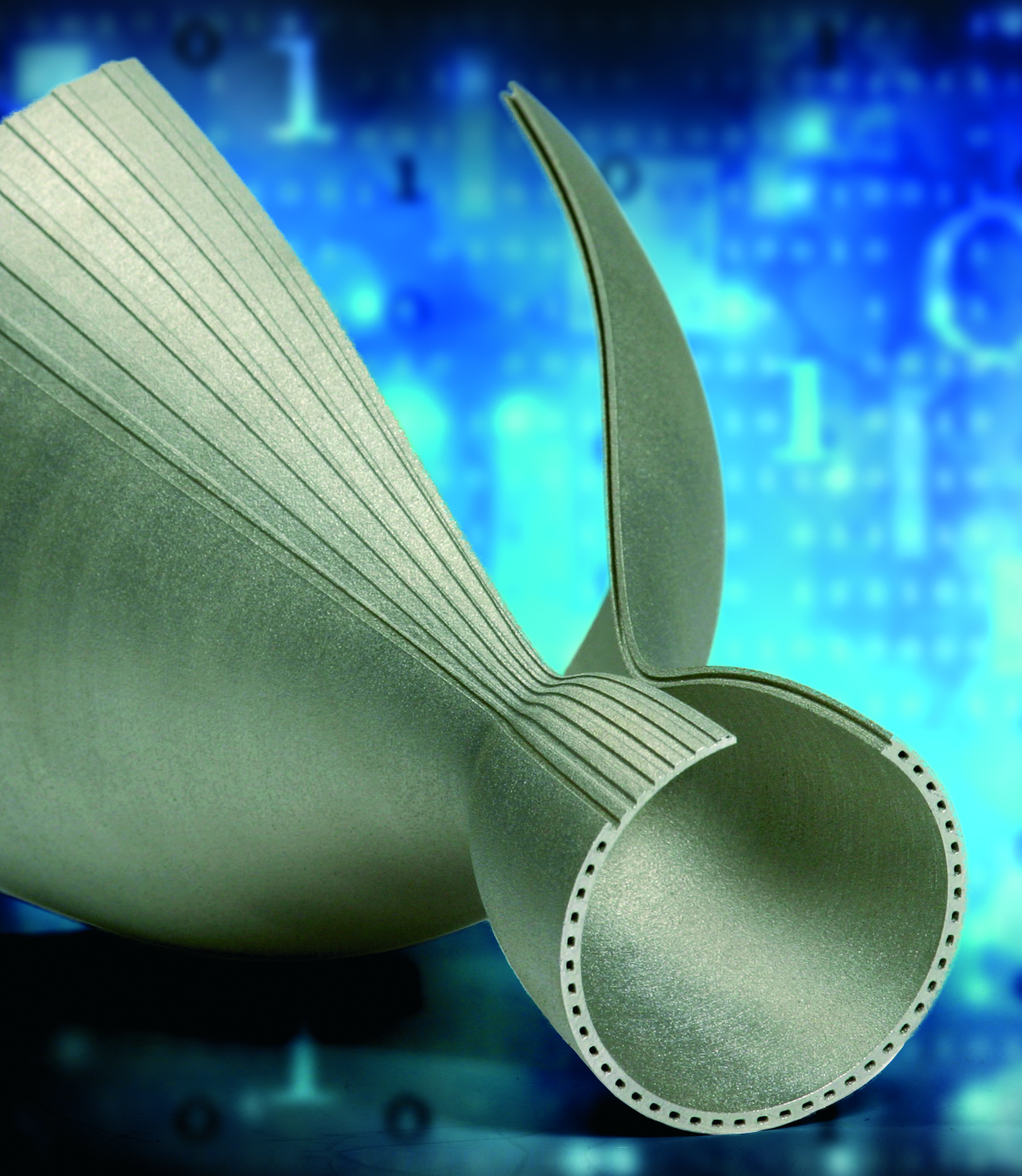

In this context, Fraunhofer IWS will present at the Hannover Messe a thrust nozzle segment manufactured by selective laser melting (SLM) with thermal-optimized cooling ducts made of stainless steel with wall thicknesses on a submillimeter scale. By optimizing the support structures and increasing the temperature of the construction chamber, the researchers succeed in improving the temperature regime in the construction process and thereby reduce thermally induced distortion.

Fraunhofer Group for Light & Surfaces at the Hannover Messe 2018

More information about the activities of the Fraunhofer Group for Light & Surfaces in surface technology and photonics as well as information on current developments at the Hannover Messe 2018 from 23-27 April at the Fraunhofer booth A30 in hall 6.

- More information

- Fraunhofer Institute for Material and Beam Technology IWS (iws.fraunhofer.de)