Hanover Trade Fair 2018: The Fraunhofer IST at the ”Digital Factory”

Digitalization and surface technology

Digitalization is a topic that affects and moves all industries. Thus, at this year’s Hanover Trade Fair from April 23 to 27, 2018 the Fraunhofer Institute for Surface Technology IST appears for the first time in the area of “Digital Factory” at the joint Fraunhofer booth “Digital Solutions & New Materials“ (hall 6, booth A30).

With its work on process simulation in the area of thin-film technology the Fraunhofer IST demonstrates to what extent digital solutions can facilitate and accelerate the development of innovative materials and surfaces. Another focal point of the institute´s presentation is the interface between physical and digital system components: In the field of Industry 4.0 thin-film sensors play an important role and find a variety of applications. Several examples are not only shown in hall 6, but also at the main Fraunhofer booth “Factory of the Future” in hall 2 (booth C22).

The focal points of the Fraunhofer IST at the Hanover Fair at a glance

Multifuncitonal thin-film sensor systems

In the age of Industry 4.0 the production of the future should be able to meet ever increasing demands: processes should be flexible, intelligently networked and sustainable, the production facilities must work safely, intuitively and at the same time resource efficiently. Thin-film sensors developed at the Fraunhofer IST provide solutions that generate measurement data where measuring systems are difficult to integrate, e. g. in main load zones in direct contact between the workpiece and tool.

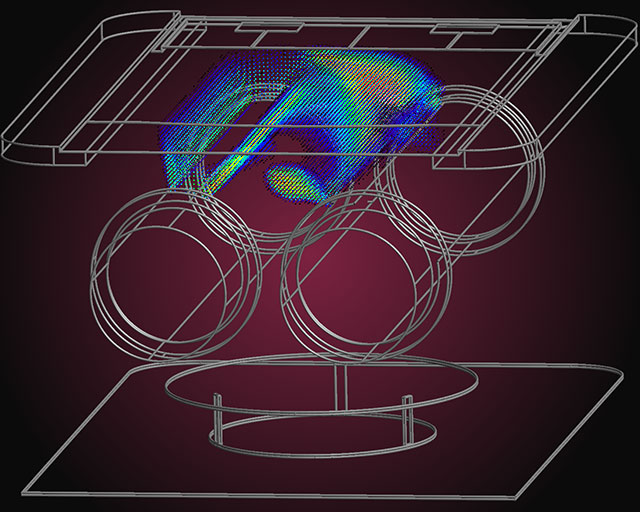

Simulation of coating processes in thin film technology

The development of precise and efficient processes in thin film technology demands a process simulation in order to obtain the required insights into process dynamics and relevant parameter correlations. At the Hannover Messe the Fraunhofer IST presents visualized results for gas and plasma simulation by means of the ”Direct Simulation Monte Carlo” and the ”Particle-in-Cell-Monte Carlo” software, which has been developed for the optimization of vacuum coating processes and systems.