Hannover Messe

Hannover Messe 2019: Flexible measuring technology for gases, liquids and solids

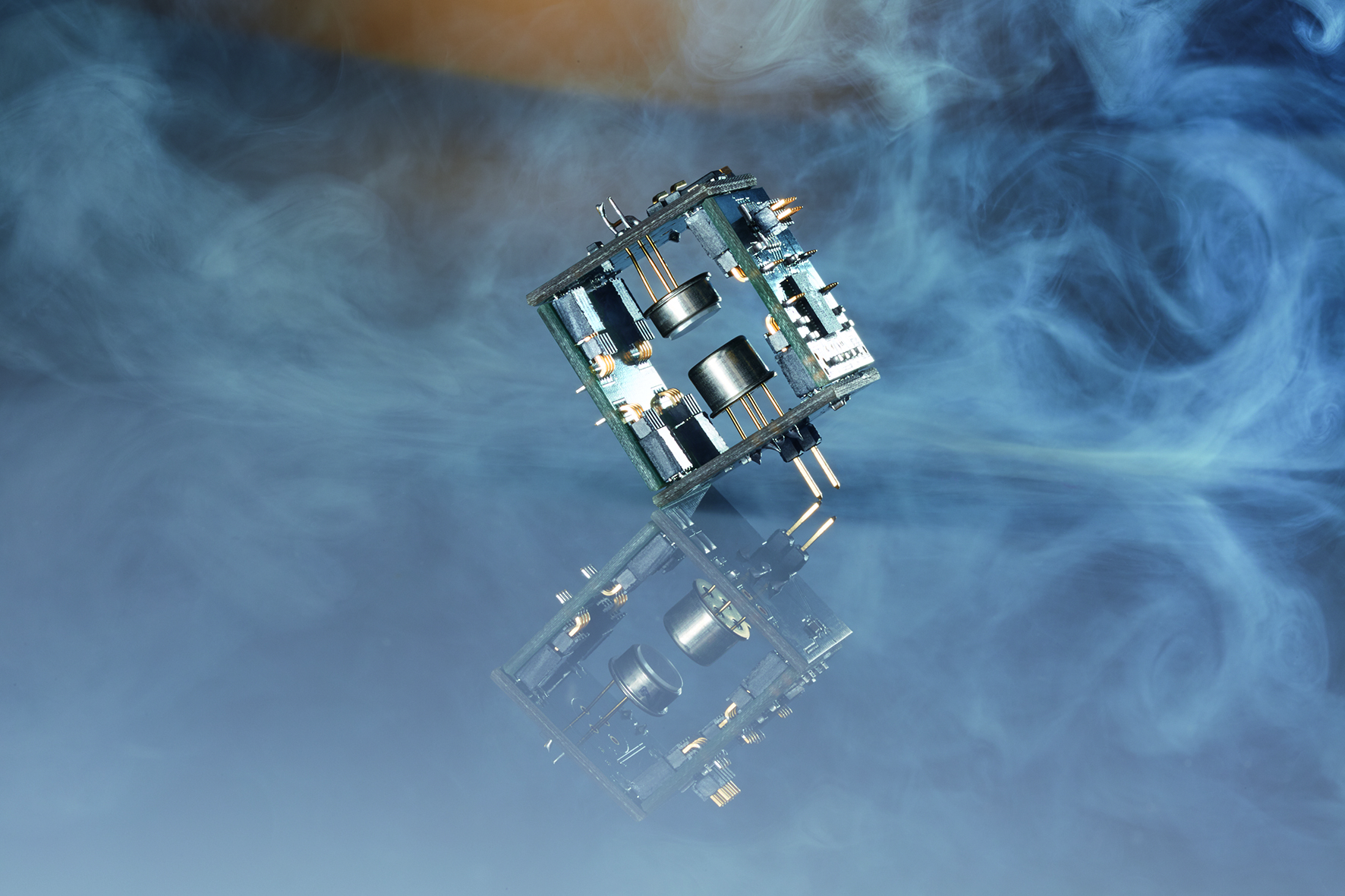

Gas sensors monitor industrial processes, detect leaks or regulate the room climate. Thanks to sophisticated technologies, the sensors measure reliably and precisely even under demanding conditions - in cars, factories and laboratories. At the Hannover Messe 2019, the Fraunhofer Institute for Physical Measurement Techniques IPM will be exhibiting three sensors encapsulated in acrylic blocks.

To combine gas sensor technology and electronics in compact microsystems that require little energy and can be manufactured cost-effectively represents a major challenge for developers. New developments such as sensor arrangements made of polyimide film open up additional applications and markets for the gas sensors of future generations. Sensor developments from Fraunhofer IPM are used in food chain management, automotive, process control and biotechnology.

Colorimetric gas sensors

Colorimetric gas sensors are used in all applications where there is only a limited amount of energy available and low-cost sensors are required. For example, this situation applies to operation in fire detectors, in Food Chain Management or in RFID labels. In such applications, colorimetric sensors can reliably detect gases such as carbon monoxide, nitrogen dioxide or ethylene. The low-cost sensors can be integrated in sensor networks and combined with other sensor principles.

Fraunhofer IPM is developing new types of low-power gas sensors based on the color change principle. A dye in combination with a polymer reacts when it comes into contact with the target gas and changes its color. This color change correlates with the concentration of the gas and has no interaction with other gases. The reaction takes place at room temperature thus meaning that no heating power is required. The power consumption is in the region of a few milliwatts. This means that, depending on measurement cycle, the system consequently operates for several years without battery changes.

Semiconductor gas sensors

Semiconductor gas sensors (or metal oxide sensors, MOX) have become smaller and more efficient in recent years. At the same time, they require less and less energy. Thanks to innovative manufacturing methods, miniaturized gas sensors can now be produced inexpensively and in large quantities. Such sensors will therefore be increasingly used not only in industry but also in everyday life of the future.

Digitization in the "smart home" and in vehicles, as well as mobile applications to monitor certain vital functions, are driving the use of miniaturized semiconductor gas sensors. In addition to established applications in safety technology, the food industry, air conditioning technology and medicine, gas sensors of the new generation will in future also be used for measurement tasks in the networked production of Industry 4.0.

Fraunhofer IPM has more than 15 years of experience in the development of semiconductor gas sensors. Research focuses on the development and modification of gas-sensitive materials, sensor substrates and processes for the economical production of materials and sensors.

Miniature photoacoustic gas measurement systems

The photoacoustic measurement method was first explained by Alexander Graham Bell in 1880. During photoacoustic measurement, rather than using a beam detector, the absorption of electromagnetic radiation by molecules is measured directly by means of a pressure transducer which detects the increase in pressure arising from the absorption.

Fraunhofer IPM has developed an innovative, compact photoacoustic system for the detection of carbon dioxide (CO2). The system combines a miniaturized measurement and reference cell with a tunable thermal emitter and a capsuled microphone. A miniature optical setup and corresponding components such as standard MEMS microphones as used in mobile communications technology make the system flexible in operation. Using these elements as active components keeps system costs low. Thanks to miniaturization and integration of the system components the photoacoustic system measures gases selectively, achieving an optimized measurement signal while at the same time consuming less power.

The Fraunhofer Group for Light & Surfaces

Further information about the Hannover Messe 2019 and on the exhibits exhibited by the Fraunhofer Light & Surfaces Group can be received on a regular basis on our homepage under “Press & Events”.

The Fraunhofer Light & Surfaces Alliance brings together the expertise of six Fraunhofer Institutes. The institutes combine coordinated competencies in the fields of laser manufacturing processes, laser beam sources, measurement technology, medicine and life sciences, optical systems and optical manufacturing, EUV technology, process and system simulation, materials technology, micro- and nanotechnology, thin-film as well as plasma and electron beam technology.